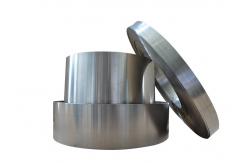

1Cr13Al4 FeCrAl Alloy Furnace Heater Strip Oxidized 1.5 - 3.0mm Thickness

|

|

FeCrAl 1Cr13Al4 Furnace Heater Strip Oxidized Thickness:1.5-3.0mm Width:10-25mm

OhmAlloy125

OhmAlloy125 is a iron-chromium-aluminium alloy (FeCrAl alloy) characterized by Stable performance,anti-oxidation,Corrosion resistance,High temperature stability,excellent coil-forming ability,uniform and beautiful surface condition without spots.It is suitable for use at temperatures up to 950°C.

Typical applications for OhmAlloy125 are used in electric locomotive, diesel locomotive,metro vehicle and high speed moving car etc brake system brake resistor,electric ceramic cooktop,industrial furnace.

1. Product Detail

1) Normal Composition(%)

2)Typical Mechanical Properties(1.0mm)

3)Typical Physical Properties

6)Temperature Factor of Electrical Resistivity

7)Style of supply

2. Production Progress

3. Question and Answer

Q1: How can I contact with your company? A1:We have multiple communication channels : Tel/Whatsapp/Wechat:+86-15826530281 QQ:3199874404(SPARROW)

Q2: Do you provide free samples? A2:Yes,we can provide free samples for your testing,but buyer should bear the shipping costs.

Q3: What is your payment terms? A3:30% in advance,balance after receiving the copy of B/L. T/T,L/C,,Paypal is OK.

Q4: What is your lead time? A4:On normal condition,the lead time is 7 days after the payment. Special order or quantity is subject to the negotiation. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: heating wire high temperature alloys | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Oxidized 2A70 Aluminum Rod For Heaters 50 Mm Dia X 1250 Mm |

|

Diameter 50mm Length 1250 Aluminum 2A70 Rod for Heater Oxidized Surface |

|

Grade 1050 / 1060 Aluminum Foil Oxidized Surface 0.1 X 310mm |

|

1.2mm SS309L FeCrAl Alloy Wire For Welding Application |

|

Cr25Al5 Dia 12mm Terminal Bar Length 405mm Thread M12 |

|

0.15*300mm Standard Type S31603 Annealed SUS316l Strip Foil For Industry |