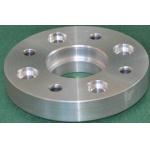

Monel K-500 K500(UNS N05500,2.4375,Alloy K-500)CNC Machining Machined Turning Turned Milling Grinding Parts Components

|

Detailed Product Description

|

We are professional Monel K-500 K500(UNS N05500,2.4375,Alloy K-500)CNC Machining Machined Turning Turned Milling Grinding Parts Components factory from china

|

Related Products

|

17-4pH(1.4542,AISI 630,17-4 pH,17/4 Ph,SUS 630,Z6CNU17-04)CNC machined Turned Milling Gear Timing Adapter Plates |

|

17-4pH(1.4542,AISI 630,17-4 pH,17/4 Ph,SUS 630,Z6CNU17-04)CNC machined Turned Milling Turning Blades for boat Sailing |

|

A182-F60(UNS S32205,AISI 318LN,SUS 329J3L)CNC Machining Machined Turning Turned Milling Grinding Parts Components |

|

A182-F310(AISI 310,UNS S31000,1.4810,A182 F310)CNC Machining Machined Turning Turned Milling Grinding Parts Components |

|

AISI 309S (UNS S30908,1.4833,AISI 309 S)CNC Machining Machined Turning Turned Milling Grinding Parts Components |

|

A182-F347(AISI 347,UNS S34700,1.4550,A182 F 347)CNC Machining Machined Turning Turned Milling Grinding Parts Components |

Email to this supplier