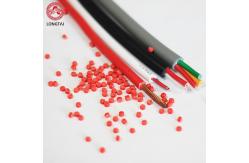

UL105C Aging Temperature 136C 168H PVC Compound for Cable Extruder

|

UL105℃ Aging Temperature 136 ℃ 168H PVC Compound for Cable ExtruderAbout PVC Compounds:

Cable PVC compounds are thermoplastic materials derived from

processing polyvinylchloride compositions, produced as granules.

Various properties are imparted to compounds depending on

applications and item operation conditions. This is achieved by

using plasticizers, stabilizers and modifiers in various

combinations in compositions.

Specification

Here are two examples:

Cable PVC Compounds Types:

Technical Data:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Hardness 90A PVC Compound PVC Compound 1.60g/cm3 Cable Extruder PVC Compound | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

REACH Compliant PVC Cable Compound For Temperature-Sensitive Applications -20C To 90C |

|

SJTW Cable Sheating Insulation Material 105℃ UL PVC Compound 1.45 Density ROHS II |

|

Cablel Use PVC Bedding Material Compound 1.55g/cm³ For Cable jacket |

|

West Asia Use PVC Compound 1.6g/Cm3 1000KGS For Special Cable Xinjiang Factory |

|

ST2 TM1 PVC Sheathing Compound For Uzbekistan Cable Wire |

|

12.5MPA Plastic PVC Compound 40-13А 8/2 -40°C- +70 °C 88A 1.5G/CM3 Cable Insulation |