Durostone Wave Soldering Pallet/Selective Soldering Pallets/Wave Pallets

|

|

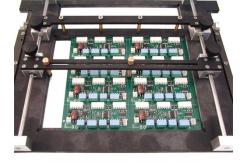

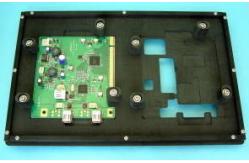

Durostone Wave Soldering Pallet/Selective Soldering Pallets/Wave Pallets Specifications 1. Eliminate the need for expensive hand masking 2. Reduce costly defects and rejects 3. Improve throughput by quality and volume Description: CW Engineering specializes in selective wave solder pallets.

Designed by engineers with extensive wave solder experience, our

pallets enable customers to automate the soldering of through-hole

components on complex electronic assemblies. The pallets only expose areas of the assembly that require

soldering. All other areas are protected, eliminating component

damage and expensive, low quality process steps. Made of ESD-safe

composite materials, these pallets are designed and manufactured to

optimize both the solder ability of your circuit boards and your

entire process flow. BENEFITS Cost Effective 1). Eliminate hand soldering processes 2) Eliminate high-defect, surface mount glue operations 3) Eliminate temporary solder masking operations 4) Reduce assembly cycle time 5) Use Fiberglass or Aluminum Stiffeners to avoid

deforming. Improves Quality 1) Improve component alignment and soldering 2) Improved solder fill and quality 3) Eliminates flooding problems Increases your flexibility 1) Eliminates board size / panelization issues 2) Standardize on conveyor width 3) Effectively process complex, double-sided surface mount

assemblies Easy to Use 1) Designed by engineers with extensive wave solder

experience 2) Optimized for easy profiling 3) Supports rapid set-up using our ergonomically designed

fasteners 4) Optimized for best soldering 5) Wave solder automation to solder through-hole components

on complex electronic assemblies. And we can design pallet for customers, if possible, please

kindly advise me below information to design pallets as your

requested.. a. CAD machined drawing or 3D drawings (such

as STP, STEP, IGS, IGES etc.) of wave solder pallets b. Gerber file of PCB board(Bare)+Sample

PCBA Board(Loaded) Specification:

Features and Benefits

Wave Soldering is a large-scale soldering process by which electronic components (pin-through-hole components) are soldered to a printed circuit board (PCB) to form an electronic assembly. CW's wave pallets or solder pallets are designed to overcome the most challenging situations. Each and every wave pallet or solder pallet is custom designed to meet your needs. Tell us your challenges - our experienced design staff has a proven solution for you.

Selective, Adjustable, and Rotating Fixtures, as well as Open Apertures

Eliminate the need for expensive hand masking Reduce costly defects and rejects Accommodate multiple cards on same pallet Improve throughput by quality and volume Prevent warping Allow standardization of conveyor width Connector hold-down eliminates lifting or skewing Wave pallets or solder pallets that work! Other advantages are: 1 Eliminate flooding by masking open areas and preventing

board sag.

Used by most of our customers because of some advantages:

TOP SIDE STANDARD FEATURES

Our goal is to design and build a solution that will give you:

Process Suitability

which CAN'T be processed (with and without glue dotting) - These

will have to be miniwaved or hand soldered.

If a PCB is available (preferably populated) - our sales engineers

can rapidly evaluate your board.

The two figures below each show part of a CSWSC in plan and section

views. The right hand figure shows that more clearance

PTH Components Located Parallel to direction through wave The clearance required between the pin land and SMT pad can be made

quite

PTH Components Located Perpendicular to direction through wave.

Working your way around the underside of the PCB, identify which

components Ideally you want to be above the line in all cases.

PCB Design Implications - for Board Designers - or respin

We are often called upon by our customers to help with identifying design respin opportunities. We will identify problem areas within a board and suggest appropriate movements of components. (Ideally before the PCB is fabricated) However for board designers reading this, can you remember another

four "rules" (to compete with the hundred other rules you have to

have floating Keep large (height) SMT components away from PTH areas.

Our production flow

CE approval

Clients from electronic industry.

|

|

Soldering Pallets,Selective Solder Tooling Adjustable Fixtures Press Fit Tooling |

|

SMT Process Carrier Wave Solder Pallet Matrix Trays Reflow Wave Solder Pallets |

|

Reflow Fixture Pallet DURAPOL Synthetic Stone and Durostone SMT Pallets |

|

Reflow Fixture Pallet DURAPOL Synthetic Stone and Durostone SMT Pallets |

|

Matrix Trays Alignment Tooling SMT Process Carrier Wave Solder Pallet |

|

Wave Pallets SMT Carriers Routing Fixtures PCB Assembly Tooling |