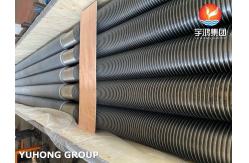

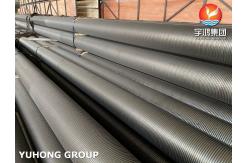

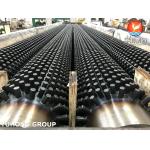

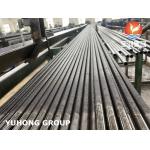

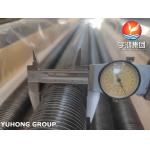

ASTM A312 TP347H High Frequency Welding Fin Tube For Furnaces Air Preheaters

|

|

We are the manufacturer of solid fin tube in China. As we have four production line of solid fin tube, we take great of our quality. We can customize the fin height, width, material and other parts according to customers' needs. Our spiral fin tube mainly used in power Plant, air preheaters, boiler, heat exchangers, inudustrial furnaces and other equipments to increase the heat exchange efficiency. And I am pleased to share following details about spiral HFW fin tube:

ASTM A312 TP347H HFW Fin Tube Mechanical Strength Tensile Strength Minimum Yield Strength: Approximately 205 MPa

(30,000 psi) Minimum Ultimate Tensile Strength: Approximately 515

MPa (75,000 psi)

FAQ: ASTM A312 TP347H High-Frequency Welded Fin Tubes

ASTM A312 TP347H is a specification for austenitic stainless steel pipes suitable for high-temperature service and corrosive environments. The "TP" stands for "Tube Product," indicating it is manufactured as a tube.

Fin tubes are tubes with extended surfaces (fins) designed to enhance heat transfer. The fins increase the surface area available for heat exchange, making them more efficient than plain tubes.

These tubes are commonly used in:Heat exchangers, Condensers, Power generation systems, Chemical processing equipment...

High Temperature Resistance: Suitable for elevated temperatures. Corrosion Resistance: Excellent for harsh environments. Improved Heat Transfer: Fins enhance thermal efficiency.

TP347H fin tubes are typically manufactured using high-frequency electric resistance welding (HF-ERW), which ensures strong and reliable welds.

Yes, TP347H fin tubes can be customized in terms of dimensions, wall thickness, and fin design to meet specific application requirements.

With proper maintenance and under appropriate operating conditions, TP347H fin tubes can have a long service life, often exceeding 20 years.

While these tubes are designed to be durable, regular inspections and cleaning may be necessary to prevent fouling and maintain optimal performance.

Consider factors such as operating temperature, pressure, fluid type, and required heat transfer efficiency. Consulting with a materials engineer can also help in making the right choice.

|

| Product Tags: ASTM A312 Fin Tube TP347H Fin Tube Furnaces Fin Tube |

|

Studded Tube , ASTM A213 T9 / ASME SA213 T11 with 11Cr (SS 409) Studded Fin Tube ,Steam Reforming Furnace |

|

ASME SA179 , ASTM A179 Carbon Steel Low Finned Tube, for Air Cooler, cooling tower application |

|

Welded Helical Serrated Fin Tubes HFW Fin Tube For Per Heating Application |

|

ASME SA210 Gr.A1 Seamless Tube with Aluminum Al1060 Embedded G type Fin tube |

|

ASTM A179/ ASME SA179 Carbon Steel Seamless Tube with Aluminum 1060, Air Cooler, Extruded Fin Tube ,Embedded G Fin Tube |

|

ASTM A179 Carbon Steel Seamless Tube with Aluminum ASTM B221 6063 (1060), Extruded Fin Tube |