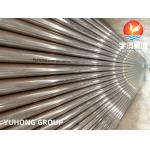

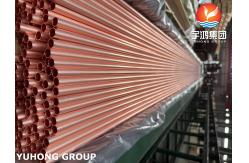

ASTM B111 / ASME SB111 C12200 Copper Tube for Condenser and Heat

Exchanger Application

ASTM B111 is a standard developed by the American Society for Testing and

Materials, which specifically specifies technical requirements for

the chemical composition, mechanical properties, dimensional

tolerances, non-destructive testing, hydrostatic testing, and other

aspects of seamless copper and copper alloy tubes used in the

manufacture of condensers, evaporators, and heat exchangers. C12200 is a specific copper alloy grade specified under this standard,

belonging to phosphorus deoxidized copper, which is a low residual

phosphorus oxygen free copper.

Why is ASTM B111 C12200 Copper Tube widely used in the Heat

Exchange Industry? - Excellent thermal conductivity: Copper has excellent thermal conductivity, second only to silver,

while C12200 copper tube has a very high thermal conductivity

coefficient (about 391 W/m · K), which is the core advantage of

making it a heat exchange tube such as condenser and heat exchange

tube, capable of efficiently transferring heat.

- Good corrosion resistance: C12200 copper tube not only has good corrosion resistance and can

maintain excellent performance in fresh water and steam condensate

water, but also has good resistance to zinc removal corrosion and

stress corrosion cracking, both of which are due to phosphorus

element. Resistance to zinc removal corrosion is a significant

advantage of phosphorus containing deoxidized copper such as C12200

compared to oxygen free copper such as C10200/C10100. In

environments containing dissolved oxygen and carbon dioxide in

brackish water, seawater, or certain water treatment chemicals,

ordinary copper nickel tubes are prone to zinc removal due to the

selective dissolution of zinc, leaving behind porous and fragile

copper structures. The phosphorus in C12200 can effectively prevent

this corrosion form from occurring, while also improving the stress

corrosion cracking resistance of copper pipes in specific media

environments such as ammonia.

- Good welding and brazing performance: The presence of phosphorus improves the welding and brazing

performance of copper tubes, making it easier to perform tube plate

connections during the manufacturing of heat exchangers.

Good mechanical and processing properties: C12200 copper tubes have sufficient strength, hardness, and

ductility, making them easy to bend, expand, and form to meet

installation requirements. Good ductility and toughness: C12200 copper tubes can maintain good toughness even at lower

temperatures. Conductivity: Due to the presence of phosphorus impurities, although the

conductivity of C12200 copper tube is slightly lower than that of

oxygen free copper such as C10200/C10100, its conductivity is still

very high, about 85-90% IACS, which is sufficient to meet the needs

of the vast majority of heat exchange applications.

ASTM B111 C12200 Copper Tube Chemical Composition | UNS NO. | ASTM B111 C12200 CHEMICAL COMPOSITION % |

|---|

| CU | Al | NI | ZI | P |

|---|

| C12200 | 99.9 | --- | --- | --- | 0.015-0.040 |

What is the difference between ASTM B111 C12200 Copper Tube and

other Copper Tubes? - Vs C11000 (ETP Copper electrolytic tough copper): C11000 has a higher oxygen content (0.02% -0.04%), which may cause

hydrogen embrittlement in reducing atmospheres such as hydrogen,

and its resistance to zinc removal corrosion is not as good as

C12200. C12200, due to deoxidation treatment, avoids hydrogen

embrittlement problems and has better resistance to zinc removal,

making it a better choice for condenser tubes.

- Vs C10200/C10100 (Oxygen Free Copper): Oxygen free copper has the highest electrical and thermal

conductivity, close to 100% IACS, and good resistance to hydrogen

embrittlement, but its resistance to zinc removal corrosion is not

as good as C12200. C10200/C10100 oxygen free copper is usually more

expensive and is commonly used in situations where high

conductivity is required for conductors or in environments that are

extremely sensitive to hydrogen embrittlement.

- VS copper-nickel alloy tubes (such as naval brass C44300, C68700

aluminum brass, CuNi 70/30, CuNi 90/10): These alloy copper tubes have better corrosion resistance in

seawater or more harsh environments, especially in terms of erosion

corrosion resistance and seawater corrosion resistance, but lower

thermal conductivity than C12200 and higher production costs.

C12200 is more cost-effective in freshwater, brackish water, or

relatively mild seawater environments.

What industries are ASTM B111 C12200 Copper Tubes mainly used in? Power plant condenser: This is the largest and most classic

application of ASTM B111 C12200 copper tubes, mainly used to

condense and return the exhaust steam from the turbine. Ship condensers and heat exchangers: ASTM B111 C12200 copper tubes

can be used for condensation and various cooling systems in ship

power plants. Heat exchangers in petrochemical, chemical, and industrial

processes: ASTM B111 C12200 can be used for cooling process fluids,

heating media, etc. Evaporators and condensers in HVAC systems, especially in chillers

and large systems. Refrigeration equipment: such as heat exchange components for large

cold storage and industrial refrigeration machines. Other heat exchange applications that require high thermal

conductivity, corrosion resistance, and good formability.

Summary:

ASTM B111 C12200 (DHP phosphorus deoxidized copper) seamless copper

tube is cost-effective and has excellent thermal conductivity, high

purity and biological inertness, excellent ductility and

formability, and no risk of hydrogen disease, making it widely used

in refrigeration systems, drinking water systems, low-pressure

heating systems, and general industrial heat exchangers that handle

non-corrosive media.

However, ASTM B111 C12200 has very poor erosion corrosion

resistance and dezincification corrosion resistance, and has low

mechanical strength. Therefore, when choosing to use ASTM B111

C12200 seamless copper tubes, it is necessary to strictly limit its

use environment, such as clean water, non-oxidizing fluids, no

solid particles, low flow rate, no chloride ions, no ammonia, etc.

Once these limits are exceeded, or chloride ions or high flow rates

appear, aluminum brass (C68700), naval brass (C44300) or

copper-nickel alloy (C70600, C71500) must be used.

|