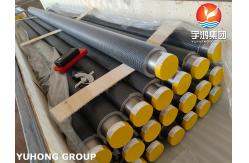

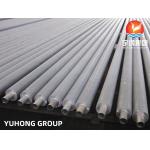

ASTM A335 P9 Spiral Finned Tube For Heat Transfer Equipments

|

|

We are the manufacturer of solid fin tube in China. As we have four production line of solid fin tube, we take great of our quality. We can customize the fin height, width, material and other parts according to customers' needs. Our spiral fin tube mainly used in power Plant, air preheaters, boiler, heat exchangers, inudustrial furnaces and other equipments to increase the heat exchange efficiency. And I am pleased to share following details about spiral HFW fin tube:

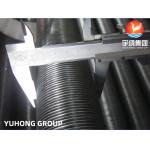

1. ASTM A335 P9 Base Tube

2. Manufacturing & Fabrication Processes Process Flow: Critical Steps: Precise heat treatment prevents grain coarsening and ensures uniform carbide distribution. B. Fin Attachment via Welding Welding Method: GTAW (TIG) for root pass + SMAW (manual arc) for fill/cap. Filler Materials: TG-S9CM (TIG wire) and R707 (low-hydrogen electrode) for P9-carbon steel joints. Pre-Weld Requirements: Preheat: 250–350°C to prevent cracking. Back purging with argon to shield against oxidation. Post-Weld Treatment: Stress relief: 300–350°C for 30 min (immediate post-heat). Full PWHT at 740–790°C to reduce hardness and residual stresses.

3. A335 P9 Solid Fin Tube Advantage Enhanced Heat Transfer: The solid fins provide a larger surface

area, improving heat transfer efficiency in heat exchangers,

economizers, and superheaters.

4. A335 P9 Solid Fin Tube Application Power Generation: Used in boiler superheaters, reheaters, and

economizers to optimize heat transfer and improve efficiency.

|

||||||||||||||||||||

| Product Tags: Spiral Finned Tube ASTM A335 P9 Finned Tube Heat Transfer Equipments Finned Tube |

|

ASTM A213 T9 Studded Alloy Steel Seamless Tube For Air Heaters And Economizers |

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Nail Head Tube Studded Tube For Petrochemical Industry |

|

ASME SA210 Gr A1 Seamless Tube Al1060 Aluminum Fin Embedded G Type Fin Tube |

|

Embedded G Type Finned Tube ASME SA210 Gr.A1 Seamless Tube With Aluminum Al1060 |