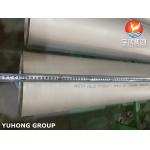

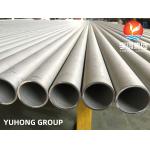

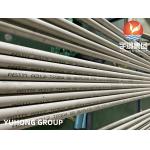

ASTM A312 TP310S Stainless Steel Seamless Pipe for Heat Exchanger

Application

ASTM A312 TP310S, as a very important high alloy austenitic heat-resistant

stainless steel pipe, is renowned for its excellent

high-temperature oxidation resistance and good corrosion

resistance, and is widely used in various oxidative environments.

According to ASTM A312 standard requirements, seamless pipes and

welded pipes can be produced. For high-temperature and

high-pressure working environments, seamless pipes are more

commonly used and cover a wide range of nominal pipe sizes. In

terms of heat treatment, ASTM A312 stainless steel pipes are often

supplied in a solution annealed state (heated to ≥ 1040 ° C and

then rapidly cooled), with the aim of dissolving carbides,

obtaining a uniform austenitic structure, optimizing corrosion

resistance, and eliminating pipe stress.

ASTM A312 TP310S Stainless Steel Seamless Pipe Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 310S | min. | – | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.08 | 2.00 | 1.50 | 0.045 | 0.030 | 26.0 | 22.0 |

The core of the composition design of TP310S stainless steel

seamless pipe lies in high chromium and high nickel. High chromium

provides the tube with top-level resistance to high temperature

oxidation and peeling, and has extremely high resistance to high

temperature corrosion in working environments with high sulfur

content. The main reason is that chromium can form a dense and

stable chromium oxide protective layer in high temperature

environments; The high nickel content gives TP310S stainless steel

seamless pipes a stable austenitic structure, preventing harmful

phase transformations, and exhibiting good resistance to reducing

acid corrosion. They can maintain good ductility and creep

resistance at high temperatures, while also improving their

resistance to carburization.

Equivalent Grades of 310S

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS |

| BS | En | No | Name |

| 310S | S31008 | 310S16 | - | 1.4845 | X8CrNi25-21 | 2361 | SUS 310S |

ASTM A312 TP310S Stainless Steel Seamless Pipe Mechanical

Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness |

| Rockwell B (HR B) max | Brinell (HB) max |

| TP310S | 515 | 205 | 40 | 95 | 217 |

ASTM A312 TP310S Stainless Steel Seamless Pipe Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) |

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C |

| 310S | 7750 | 200 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 720 |

ASTM A312 TP310S Stainless Steel Seamless Pipe Application

TP310S stainless steel seamless pipes are widely used in industrial

fields that require long-term exposure to high-temperature

oxidation environments:

Heat treatment and metallurgical industry: furnace cans, muffle tubes, guide rails, material trays, radiation

tubes, fan blades, hot air ducts, high-temperature fixtures, and

material baskets for annealing furnaces, carburizing furnaces,

tempering furnaces, and sintering furnaces.

- Petrochemical and chemical industries: components of ethylene cracking furnaces, hydrogen production

conversion furnaces, reforming furnaces, high-temperature heat

exchanger tubes, high-temperature reactor liners, and pipelines.

- Energy and Power: Superheater and reheater tubes for power plant boilers,

superheater and evaporator tubes for waste incinerators, and

components for heat recovery steam generators.

- Ceramic and glass industry: roller bars for kilns, furnace supports, burner nozzles,

high-temperature conveying pipelines.

Other: High temperature valves, flanges, expansion joints; High

temperature sensor protective sleeve; Automotive exhaust system

components.