L Type Fin Tube Wound Fin Tube ASME SA249 TP316L With Al1100 For

Air Cooler

Product OverviewThe ASME SA179 Extruded Fin Tube with Al1100 Fin Strip is a high-performance tube designed for air cooler applications where efficient heat transfer and corrosion resistance are essential. Made from ASME SA179 carbon steel, which is a seamless low-carbon steel, the tube is equipped with extruded aluminum fins (Al1100) that significantly enhance its surface area for heat dissipation. This combination provides optimal performance in air-cooled heat

exchangers, cooling towers, and other HVAC systems where high heat transfer efficiency is required in space-constrained environments.

Key Features1. Base Tube Material: ASME SA179 Carbon SteelASME SA179 is a low-carbon steel designed for seamless tube applications, offering excellent thermal conductivity and mechanical strength. This material is commonly used in heat exchangers, boilers, and cooling systems where high-temperature and high-pressure conditions exist. Low-carbon steel provides good weldability and formability, making it a versatile choice for various industrial heat transfer

applications.

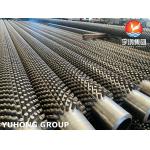

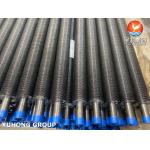

2. Fin Type: Extruded Aluminum FinThe extruded aluminum fins (made of Al1100) are designed to enhance the heat transfer capabilities of the

tube. Extrusion ensures that the fins have excellent thermal conductivity and are mechanically bonded to the base tube, which prevents

detachment over time. Al1100 aluminum is widely used in heat transfer applications due to its high corrosion resistance and lightweight nature.

3. Fin Material: Al1100 AluminumAl1100 is a pure aluminum alloy with excellent thermal conductivity and corrosion resistance, making it ideal for cooling systems that need to operate in humid or chemically aggressive environments. Aluminum fins provide efficient heat dissipation in air-cooled heat exchangers, cooling towers, and HVAC systems, where maximizing heat exchange in a compact form is required.

4. Application: Air Coolers, Heat Exchangers, Cooling TowersThe extruded fin tube design is highly effective in air-cooled heat exchangers and cooling systems, where space-efficient heat dissipation is necessary. The tube is ideal for use in industrial cooling systems, HVAC, and petrochemical applications, where high thermal efficiency and reliable performance are critical for system operation.

Chemical Composition

Base Tube: ASME SA179 Carbon SteelFin Material: Al1100 Aluminum

Mechanical PropertiesBase Tube: ASME SA179 Carbon SteelFin Material (Al1100 Aluminum)Advantages of L Type Fin Tube

ApplicationsAir Coolers: Ideal for use in air-cooled heat exchangers and cooling systems where high heat transfer efficiency is required in compact designs. Heat Exchangers: Applied in industrial heat exchangers, chemical processing, and petrochemical plants where efficient heat exchange is needed. Cooling Towers: Effective in cooling tower systems for HVAC applications, refrigeration, and industrial cooling. HVAC Systems: Used in air conditioning systems and industrial cooling systems where compact, high-efficiency cooling is necessary.

|