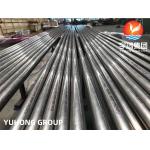

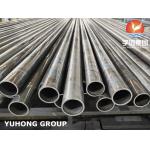

ASTM A334 GR.6 Tubes – High-Performance Corrosion Resistance

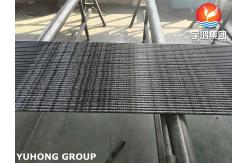

1.Product Overview

ASTM A334 GR.6 (UNS N10276) tubes are made from Hastelloy C-276, a nickel-chromium-molybdenum alloy engineered for exceptional

resistance to harsh environments, including oxidizing and reducing

acids, chlorides, and seawater. Ideal for chemical processing,

pollution control, and offshore applications.

2. Chemical Composition (ASTM B334 GR.6)

| Element | Composition (% Weight) |

|---|

| Nickel (Ni) | Balance (≥52%) | | Chromium (Cr) | 14.5–16.5 | | Molybdenum (Mo) | 15.0–17.0 | | Iron (Fe) | 4.0–7.0 | | Tungsten (W) | 3.0–4.5 | | Cobalt (Co) | ≤2.5 | | Manganese (Mn) | ≤1.0 | | Silicon (Si) | ≤0.08 | | Carbon (C) | ≤0.02 | | Sulfur (S) | ≤0.01 |

3. Equivalent Grades

| Property | Value (Room Temperature) |

|---|

| Tensile Strength | ≥690 MPa (100 ksi) | | Yield Strength (0.2% Offset) | ≥283 MPa (41 ksi) | | Elongation | ≥40% | | Hardness (Rockwell B) | ≤100 HRB |

4. Key Advantages- Superior Corrosion Resistance: Resists pitting, crevice corrosion, and stress corrosion cracking

(SCC) in chloride-rich environments.

- High-Temperature Stability: Maintains strength up to 400°C (752°F).

- Weldability: Compatible with GTAW, GMAW, and SMAW processes without post-weld

heat treatment.

- Versatility: Suitable for both oxidizing (e.g., HNO₃) and reducing (e.g., HCl)

media.

5. Applications of ASTM A334 GR.6 Tubes- Chemical Processing: Reactors, heat exchangers, and piping for sulfuric, hydrochloric,

and acetic acid.

- Pollution Control: Flue gas desulfurization (FGD) systems and scrubbers.

- Oil & Gas: Offshore platforms, seawater cooling systems, and sour gas

pipelines.

- Pharmaceutical: Equipment handling aggressive solvents.

|