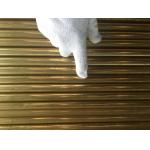

ASTM B111 C70600 Seamless Tubes 90 10 Cu-Ni Alloy

|

Detailed Product Description

ASTM B111 C70600 Copper-Nickel Tubes: High-Performance Corrosion-Resistant Alloy |

| Element | Composition (%) | Role |

|---|---|---|

| Copper (Cu) | 86.0–89.0 | Base metal, ensures conductivity |

| Nickel (Ni) | 9.0–11.0 | Enhances corrosion resistance |

| Iron (Fe) | 1.0–2.0 | Improves erosion resistance |

| Manganese (Mn) | 0.5–1.0 | Stabilizes microstructure |

| Zinc (Zn) | ≤1.0 | Trace impurity control |

| Lead (Pb) | ≤0.05 | Minimizes environmental toxicity |

ASTM B111 C70600 Equivlent Grades

| Standard | Equivalent Grade | Region/System |

|---|---|---|

| UNS | C70600 | Unified Numbering System |

| EN | CW352H | European Norm |

| DIN | 2.0872 | German Standard |

| JIS | C7060 | Japanese Industrial Standard |

ASTM B111 C70600 Mechanical Properties

Key mechanical performance data for engineering design:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 310–380 MPa (45–55 ksi) | ASTM E8/E8M |

| Yield Strength (0.2%) | 125 MPa (18 ksi) min | ASTM E8/E8M |

| Elongation | 35% min (50 mm gauge length) | ASTM E8/E8M |

| Hardness | 65–85 HRB | ASTM E18 |

| Max Operating Temp | 400°C (750°F) | ASTM B111 |

Key Advantages of ASTM B111 C70600 Tubes

- Superior Corrosion Resistance: Resists pitting, crevice corrosion, and biofouling in seawater and brackish environments.

- High Thermal Conductivity: 29 W/m·K (50 BTU·in/hr·ft²·°F), ideal for heat exchangers and condensers.

- Ease of Fabrication: Compatible with welding, brazing, and bending without cracking.

- Long Service Life: 20+ years in marine applications with minimal maintenance.

ASTM B111 C70600 Applications

| Industry | Applications |

|---|---|

| Marine Engineering | Seawater piping, desalination plants, ship hulls, offshore platforms |

| Power Generation | Condenser tubes, heat exchangers, cooling systems |

| Oil & Gas | Subsea pipelines, LNG processing, refinery cooling systems |

| Chemical Processing | Acid-resistant tubing, evaporators, distillation columns |

Related Products

|

C68700 Copper Alloy Seamless Tube ASTM B111 For Heat Exchangers SGS Approved |

|

ASME SB111 C68700 Aluminum Brass Seamless Tube O61 for Heat Exchanger Tube Bundle |

|

ASME SB111 UNS C71500 O61 CuNi 70/30 2.0882 Copper Nickel Alloy Seamless Tube |

|

90/10 Copper-nickel Alloy Seamless Tube , ASTM B111 C70600 , Apply To Offshore And Marine Engineering |

|

Cold Finished ASME SB111 C44300 Copper Alloy Tubeb |

|

ASME SB111 / ASTM B111 C71640 (CuNi 70/30, CW353H),Copper Nickel Alloy Steel Tube / Condenser Tube |

Email to this supplier