HFW Serrated Fin Tube ASTM A312 TP304H Stainless Steel With SS304

Convection Coil ApplicationProduct Overview:The HFW Serrated Fin Tube ASTM A312 TP304H Stainless Steel with SS304 is specifically designed for use in convection coil applications, where high thermal efficiency and corrosion resistance are essential. The tube is made from ASTM A312 TP304H stainless steel, offering exceptional high-temperature strength and corrosion resistance, ideal for furnaces, boilers, and heat exchangers. The serrated fin design significantly increases the surface area for heat transfer,

enhancing the thermal performance of convection coils and ensuring that the system can efficiently handle high-pressure

and high-temperature environments.

Key Features1. Base Tube Material: ASTM A312 TP304H Stainless SteelASTM A312 TP304H is a high-carbon version of SS304 stainless steel, known for its enhanced mechanical properties at high temperatures. It provides excellent resistance to oxidation and corrosion, especially in high-temperature environments, making it ideal for use in convection coils, boilers, heat exchangers, and other high-performance heat transfer systems. 304H stainless steel also ensures long-term reliability in furnaces and energy recovery systems, where both strength and thermal stability are crucial.

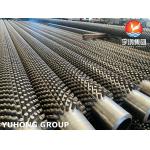

2. Fin Type: Serrated Fin DesignThe serrated fin design enhances heat transfer by creating turbulence in the surrounding air or fluid, reducing the thermal boundary layer and increasing the efficiency of heat dissipation. This design significantly increases the surface area for heat exchange while reducing airflow resistance, making it ideal for use in convection coils and cooling systems that require efficient heat exchange in compact spaces.

3. Fin Material: SS304 Stainless SteelThe SS304 stainless steel fins are highly resistant to corrosion and oxidation, providing durability and long service life in environments exposed to moisture, high-temperature steam, and flue gases. SS304 is also highly resistant to stress corrosion cracking, which is essential for convection coils in high-temperature, high-pressure systems such as furnaces and heat exchangers.

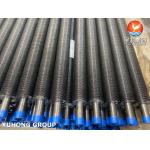

4. Application: Convection Coils, Heat Exchanger, Boiler, FurnaceThe HFW serrated fin tube is ideal for convection coils in furnaces, boilers, and heat exchangers, where efficient heat transfer and reliable performance are required under high-temperature and high-pressure conditions. The serrated fin design ensures that the tube performs effectively in industrial heating systems, power generation, and energy recovery applications, where maximizing heat dissipation and thermal efficiency is essential.

Chemical Composition| Element | ASTM A312 TP304H Stainless Steel (Base Tube) |

|---|

| Carbon (C) | 0.04% - 0.10% | | Manganese (Mn) | 2.00% max | | Chromium (Cr) | 18.00% - 20.00% | | Nickel (Ni) | 8.00% - 10.50% | | Molybdenum (Mo) | 0.75% max | | Iron (Fe) | Balance | | Sulfur (S) | ≤ 0.030% | | Phosphorus (P) | ≤ 0.030% |

Advantages of HFW Fin Tubes in Economizers for High-Pressure

ApplicationsEnhanced Heat Transfer Efficiency: High-Temperature Performance: Corrosion Resistance: SS304 stainless steel fins offer superior resistance to corrosion and oxidation, ensuring that the tube maintains its structural integrity even in harsh, high-temperature environments, including exposure to moisture, steam, and flue gases.

Durability and Long Service Life: Compact Design:

ApplicationsConvection Heat Exchanger Tubes: Ideal for use in high-pressure applications in power plants, boilers, superheaters, and furnaces. Furnace and Heat Recovery: Used in furnaces and waste heat recovery systems where efficient heat exchange is required under high-pressure conditions. Industrial Cooling Systems: Used in high-temperature cooling systems in petrochemical plants, oil refineries, and other industrial settings requiring reliable heat

dissipation.

|