1. Brief introduction

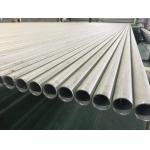

ASTM A249 TP316L(UNS S31603) is an ultra-low-carbon austenitic stainless steel welded tube.

Adding molybdenum (2.0-3.0%) significantly improves the resistance to chloride corrosion and

pitting corrosion. Its carbon content is ≤0.03%, effectively

avoiding the precipitation of carbides in the heat-affected zone of

welding and ensuring the welded joint's intergranular corrosion

resistance. It is widely used in pressure-bearing equipment in

high-temperature and corrosive environments.

2. Chemical composition of ASTM A249 TP316L tube (wt%)

| Element | Range |

|---|

| C | ≤0.030 |

| Cr | 16.0-18.0 |

| Ni | 10.0-14.0 |

| Mo | 2.00-3.00 |

| Mn | ≤2.00 |

| Si | ≤1.00 |

| P | ≤0.045 |

| S | ≤0.030 |

| Fe | margin |

3. Comparison of equivalent grades

- EN: 1.4404 / X2CrNiMo17-12-2

4. Mechanical properties (solution annealed state)

| Parameters | Numeric |

|---|

Tensile strength (Rm)

| ≥485 MPa |

Yield strength (Rp0.2)

| ≥170 MPa |

Elongation (50mm gauge length)

| ≥35% |

Hardness (HB)

| ≤217 |

5. Application areas of ASTM A249 TP316L Welded Stainless Steel

Tube

- Petrochemical energy: refinery heat exchanger tubes, LNG cryogenic pipelines.

- Pharmaceutical equipment: bioreactors, clean piping systems (ASME BPE standard).

- Marine engineering: desalination units, marine condensers.

- Food processing: pasteurization pipelines, fermentation tanks.

- Environmental protection equipment: flue gas desulfurization (FGD) systems, wastewater treatment heat

recovery units.

6. Additional Notes

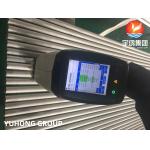

- Testing standards: 100% eddy current testing (ASTM E426), water pressure/air pressure

test (optional).

- Surface treatment: pickling and passivation (ASTM A380), electrolytic polishing

(Ra≤0.5μm).

- Supply specifications: outer diameter 6-1200mm, wall thickness 0.5-25mm, support

customized U-shaped/coil.