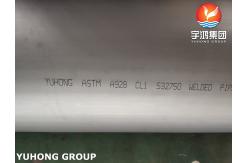

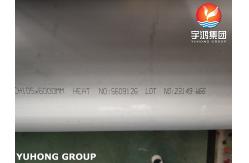

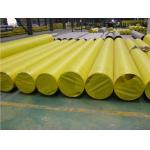

ASTM A928 CL.1 Super Duplex Steel Welded Pipes S32750 S32205 S31254

|

|

ASTM A928 CL.1 Super Duplex Steel Welded Pipes S32750 S32205 S31254

Key Features of ASTM A928 Pipes

- Manufacturing Process: - Electric Fusion Welding (EFW) with filler metal added (e.g., SAW, TIG). Welds are heat-treated to restore duplex microstructure and corrosion resistance. - Testing Requirements: - Hydrostatic Testing: Mandatory for all pipes. - Non-Destructive Examination (NDE): Radiography or ultrasonic testing for welds. - Mechanical Testing: Tensile, hardness, and impact tests.

Classes of ASTM A928 Welded / EFW Pipe

Duplex Stainless Steel have a structure that contains both ferrite and austenite. Duplex alloys have higher strength and better stress corrosion cracking resistance than most austenitic alloys and greater toughness than ferritic alloys, especially at low temperatures. The corrosion resistance of duplex alloys depends primarily on their composition, especially the amount of chromium, molybdenum, and nitrogen they contain.

Application:

Key Benefits of ASTM A928 Pipes

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: S31254 Welded Pipes S32750 Welded Pipes S32205 Welded Pipes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM A270/ ASME SA270 Sanitary Pipe TP316L Stainless Steel Welded Pipe |

|

Stainless Steel Welded Pipes, ASTM A358 CLASS 1, TP304L , TP316L , TP321, Petrolchemical application , 100% RT |

|

Stainless Steel Welded Pipe,JIS G3459 SUS316L , SUS304L, 125 A , 150A , SCH 40 , 6M Pickled and Annealed, Plain End |

|

ASTM A312 TP316L Stainless Steel Welded Pipe |

|

ASTM A358 / ASME SA358 TP316L Stainless Steel Welded Pipe Pickled and Annealed |

|

ASTM A312 TP316L Stainless Steel Pipe Large Outside Diameter For High Resistant To Chloride Corrosion |