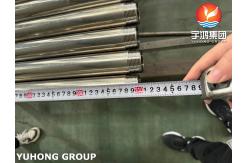

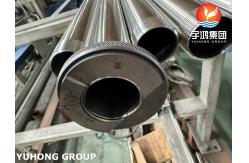

ASTM A270 TP304 Sanitary Stainless Steel Tube With External Thread End

|

|

ASTM A270 TP304 Sanitary Stainless Steel Tube With External Thread End

ASTM A270 TP304 stainless steel pipe is the gold standard of the sanitation industry. With its excellent cleanliness, corrosion resistance and formability, it is widely used in high-demand fields such as food and pharmaceuticals. It is suitable for industries with extremely high requirements for cleanliness and corrosion resistance. When selecting, the surface treatment level (such as electrolytic polishing) and connection method should be given priority, and it should be avoided in strong corrosion or high temperature extreme environments.

Advantage

1. Fast and reliable connection No welding required: Directly screw into the matching port through the thread, simplifying the installation process, especially suitable for places with limited space or prohibited hot work. Time and labor saving: Compared with flange connection, threaded connection is lighter and the installation tools are simple.

2. Disassembly and convenient maintenance Modular design: Allows the removal and replacement of pipe sections or components at any time, which is convenient for maintenance, cleaning or system modification. Reduce downtime: No need to cut the pipe during maintenance, greatly shortening the maintenance cycle.

3. Sealing function Combined with sealing materials: Threads can be used with raw tape, sealant or gaskets to form high-pressure seals Sealing types: Tapered threads (such as NPT): The threads themselves bite to produce a seal (auxiliary sealants are required). Straight threads (such as BSPP): Rely on end face gaskets for sealing, and the threads only provide tightening force.

4. System flexibility Adapt to a variety of interfaces: Easily connect pipes of different specifications or materials through thread conversion joints. Extended function: The end can be connected to accessories such as pressure gauge, sensor, exhaust valve, etc. to achieve monitoring or control.

Chemistry Composition

Mechanical Properties

Outside Diameter & Tolerance

Application

1. Food and beverage processing Prevent bacterial growth Resistant to lactic acid and detergent corrosion

2. Pharmaceutical and bioengineering

3. Cosmetics and daily chemical products High-precision delivery tube to ensure no particle contamination Resistant to alcohol and organic solvents.

4. Medical and laboratory equipment Medical gas delivery

5. Semiconductor and electronics industry

|

|

ASTM A268 TP430Ti / UNS S43036 / 1.4510 Stainless Steel Seamless Tube |

|

Stainless Steel Seamless Tube ASTM A269 TP304L Pickled and Annealed Tubing |

|

ASTM A213 TP316L Stainless Steel Seamless Tube For Storage Tanks And Refineries |

|

ASTM A270 TP316L Stainless Steel Sanitary Seamless Tube Bright Surface |

|

SS ASME SA269 / ASTM A269 TP316L Seamless Tube Bright Annealing |

|

ASTM A270 TP316L Sanitary Stainless Steel Tube Seamless Tube for Chemical Engineering |