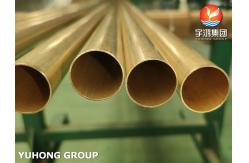

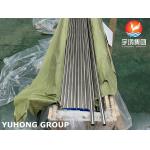

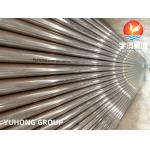

JIS H3300 C6872T / ASTM B111 C68700 Aluminum Brass Tube Heat Exchanger Tube

|

|

JIS H3300 C6872T Seamless Aluminum Brass Alloy Tube Heat Exchanger Tube

JIS H3300 is Japanese Industrial Standard for Copper and Copper Alloy Seamless Tubes. C6872 is an aluminum brass alloy, primarily composed of copper (Cu), zinc (Zn), and aluminum (Al). This material has excellent resistance to seawater corrosion and biofouling, making it ideal for marine applications; higher mechanical strength compared to standard brass alloys due to the addition of aluminum; good thermal conductivity, suitable for heat exchangers and condensers. It's an be easily formed, welded, and brazed.

The Equivalent Grade of C68700 Aluminum Brass Alloy Tube

The advantages of JIS H3300 C6872T Aluminum Brass Alloy 1. Excellent Corrosion Resistance Seawater Resistance: C6872T exhibits outstanding resistance to seawater corrosion, making it ideal for marine applications such as shipbuilding, offshore platforms, and desalination plants.

Dezincification Resistance: The addition of arsenic (As) in the alloy prevents dezincification, a common form of corrosion in brass alloys where zinc is selectively leached out, leaving a porous copper structure.

Biofouling Resistance: The aluminum content in C6872T provides resistance to biofouling (the accumulation of microorganisms, algae, or plants on surfaces exposed to water), reducing maintenance costs and improving operational efficiency.

2. High Mechanical Strength C6872T has higher tensile and yield strength compared to standard brass alloys, thanks to the addition of aluminum. This makes it suitable for applications requiring durability and resistance to mechanical stress.

3. Good Thermal Conductivity With a thermal conductivity of approximately 109 W/m·K, C6872T is an excellent material for heat exchangers and condensers. It ensures efficient heat transfer, which is critical in cooling systems and power generation equipment.

4. Ease of Fabrication Formability: C6872T can be easily formed, bent, and shaped without cracking, making it suitable for complex geometries in heat exchangers and condenser tubes. Weldability and Brazability: The alloy can be welded and brazed using standard techniques, allowing for easy assembly and repair in industrial applications.

5. Resistance to Stress Corrosion Cracking (SCC) C6872T is highly resistant to stress corrosion cracking, a common issue in environments with high chloride concentrations (e.g., seawater). This makes it a reliable material for marine and offshore applications. Application

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Heat Exchanger Aluminum Brass Tube JIS H3300 C6872T Aluminum Brass Tube ASTM B111 C68700 Aluminum Brass Tube | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

C68700 Copper Alloy Seamless Tube ASTM B111 For Heat Exchangers SGS Approved |

|

ASME SB111 C68700 Aluminum Brass Seamless Tube O61 for Heat Exchanger Tube Bundle |

|

ASME SB111 UNS C71500 O61 CuNi 70/30 2.0882 Copper Nickel Alloy Seamless Tube |

|

90/10 Copper-nickel Alloy Seamless Tube , ASTM B111 C70600 , Apply To Offshore And Marine Engineering |

|

Cold Finished ASME SB111 C44300 Copper Alloy Tubeb |

|

ASME SB111 / ASTM B111 C71640 (CuNi 70/30, CW353H),Copper Nickel Alloy Steel Tube / Condenser Tube |