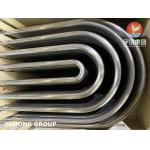

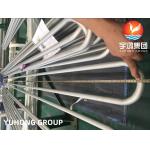

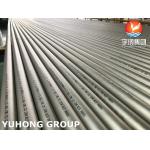

ASME SA209 T1a Seamless Carbon Molybdenum U Bend Tube Heat Exchanger Tube

|

|

ASTM A209 / ASME SA209 T1A Low Alloy Steel Seamless U Bend Heat Exchanger Tube

ASME SA209 T1A is a material specification for seamless carbon steel tubes primarily used in boiler and superheater applications. This alloy provides good strength at elevated temperatures and moderate resistance to oxidation and creep, making it suitable for high-temperature and high-pressure environments. However, for more aggressive corrosion and higher temperature, other alloys like T22, T91 or Inconel might be used.

Advantages of ASME SA209 T1A Low Alloy Steel Seamless Tubes

Equivalent Designation

ASTM A209/ ASME SA209 T1, T1a, T1b Alloy Steel SeamlessTubes Chemical Composition

Tensile Requirements and Hardness

1>. Flattening Test The flattening test of Specification A999/A999M shall be made on a specimen from one end or both ends of each pipe. Crop ends may be used. If this supplementary requirement is specified, the number of tests per pipe shall also be specified. One flattening test shall be made on specimens from each end of one finished tube, not the one used for the flaring test, from each lot. 2>. Flaring Test One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot. 3>. Hydrostatic or Nondestructive Electric Test Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the purchase order. 4>. Bend Test For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test. Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser

Alternative grades of ASME SA209 T1A Alloy Steel Seamless Tubing

PT / Penetration Test of U Bend Area

Applications:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Heat Exchanger U Bend Tube ASME SA209 U Bend Tube Seamless Carbon-Molybdenum U Bend Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |