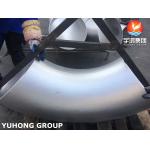

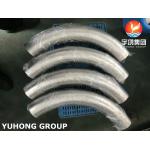

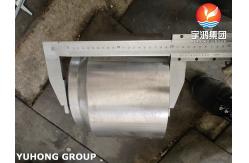

ASME SA105N Carbon Steel Self Reinforced Nozzle for heat exchanger Key Features:- Material: ASME SA105N Carbon Steel, an alloy designed for excellent mechanical properties and

corrosion resistance, making it ideal for high-pressure and

high-temperature environments, such as heat exchangers.

- Design: Self-Reinforced Nozzle, which provides enhanced strength and stability, allowing for

effective attachment and sealing between the nozzle and the heat

exchanger shell.

- Application: Specifically engineered for heat exchangers, these nozzles are designed to ensure a secure and robust

connection to pipe systems, providing both mechanical support and

fluid-tight integrity.

Chemical Composition:| Element | ASME SA105N (Carbon Steel) |

|---|

| Carbon (C) | 0.35% (max) | | Manganese (Mn) | 0.60% - 1.00% | | Phosphorus (P) | 0.035% (max) | | Sulfur (S) | 0.035% (max) | | Silicon (Si) | 0.10% - 0.40% | | Chromium (Cr) | ≤ 0.30% | | Nickel (Ni) | ≤ 0.25% |

Mechanical Properties:| Property | ASME SA105N (Carbon Steel) |

|---|

| Tensile Strength | 485 MPa (min) | | Yield Strength | 205 MPa (min) | | Elongation | 20% (min) | | Hardness | Brinell hardness: 119 (max) |

Advantages:- High Strength and Durability: SA105N carbon steel provides the necessary strength to withstand

high-pressure conditions in heat exchangers, ensuring a

long-lasting and reliable performance.

- Cost-Effective: As a commonly used material, SA105N carbon steel is a

cost-effective solution for nozzles in heat exchangers while still

offering good mechanical properties.

- Corrosion Resistance: While not as corrosion-resistant as stainless steel, SA105N

offers good resistance to oxidation and corrosion in non-extreme

environments, ensuring extended service life.

- Self-Reinforced Design: The self-reinforced structure adds strength and stability,

reducing the need for additional reinforcements and simplifying the

nozzle design.

Applications:- Heat Exchangers: Used in both shell-and-tube and air-cooled heat exchangers,

connecting piping systems to heat exchanger units.

- Pressure Vessels: Providing a secure connection between piping and the vessel

itself, especially in high-pressure applications.

- Chemical Processing: For applications in chemical and petrochemical industries, where

the nozzle provides a reliable interface for fluid transfer.

- Power Plants: For use in the cooling systems of boilers, condensers, and heat

exchangers in power plants.

|