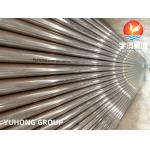

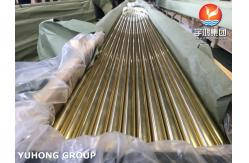

ASTM B111 C44300 Copper Nickel Tube for Condenser and Heat

Exchanger Application

ASTM B111 C44300 copper tubes complies with ISO standards m-2004 and B171m-2004, as

well as ASTM B111/B111M-2009 (American Standard Copper and Copper

Alloy Seamless Condenser Tubes and Casings). C44300 tin brass is a

high copper alloy that usually has a high copper content and

contains a certain amount of tin and other alloying elements such

as zinc and trace amounts of arsenic. The addition of these

elements gives C44300 tin brass unique properties.

- Mechanical properties: It has good mechanical properties, including high tensile strength

and elongation. This makes C44300 tube perform well when

subjected to mechanical stress such as pressure and stretching.

- Corrosion resistance: It has excellent corrosion resistance, especially in environments

with corrosive liquids. The addition of trace arsenic can inhibit

dezincification corrosion and further improve the corrosion

resistance of the alloy. Recent studies have also shown that the

addition of trace elements such as boron and nickel can further

enhance its corrosion resistance.

- Hot and cold processing performance: C44300 tin brass has excellent cold processing performance and is

easy to process into various shapes and sizes. At the same time, it

also has certain hot processing performance and can be hot pressed,

hot rolled and other processes at a certain temperature.

ASTM B111 C44300 Copper Tubing Chemical Composition | UNS NO. | ASTM B111 C44300 CHEMICAL COMPOSITION % |

|---|

| CU | TI | FE | ZI | AS | MN |

|---|

| C44300 | 70.0-73.0 | 0.9-1.2 | 0.06 MAX | REM | 0.02-0.06 | ---

|

ASTM B111 C44300 Copper Nickel Tube Tensile Requirements | UNS NO. | Temper Designation | Tensile Strength min, ksi | Yield Strength min, ksi |

|---|

| Code | Name |

|---|

C44300 | O61 | Annealed | 45 | 15 |

ASTM B111 C44300 Copper Nickel Tube Application: - Marine engineering field: C44300 copper nickel tubes play an important role in shipbuilding.

Their excellent seawater corrosion resistance makes them an ideal

material for manufacturing hulls and marine equipment. In

particular, they are used to manufacture parts that come into

contact with seawater, such as heat exchangers, condensers,

evaporators, etc. In offshore oil and gas production, C44300 copper

nickel tubes are also often used to manufacture equipment such as

heat exchangers and condensers on offshore platforms, as well as

other parts that need to withstand seawater corrosion.

- Power industry: C44300 copper nickel tubes are widely used in inland thermal

power plants, especially for manufacturing high-strength,

corrosion-resistant heat exchanger condenser tubes. These devices

need to be in contact with corrosive media for a long time, and the

corrosion resistance of C44300 copper nickel tubes just meets

these needs; although nuclear power plants have more stringent

requirements on materials, C44300 copper nickel tubes are also used

in auxiliary systems of some nuclear power plants, such as for

manufacturing cooling system tubes.

- Food processing field: Because C44300 copper nickel tubes have good corrosion resistance

and hygienic properties, they are also commonly used in the

manufacture of food processing equipment, such as pipelines and

containers for the manufacture of dairy products, beverages and

other foods.

- Construction and decoration field: Due to its excellent corrosion resistance, C44300 copper nickel

tubes are often used to manufacture roofs, rainwater tubes and

other parts that are susceptible to rain erosion; C44300 copper

nickel tubes can also be used to make various decorations and

artworks, such as sculptures, lamps, etc.

What are the differences in application areas between ASTM B111

C44300 and ASTM B111 C68700? - ASTM B111 C44300 (Navy Brass) copper nickel tube is suitable for various seawater

cooled condensers, evaporators, and heat exchangers (marine, power

plant, industrial refrigeration), especially for low to medium flow

rate seawater, relatively clean water quality, or environments with

less suspended solids. At the same time, due to its better

resistance to ammonia corrosion, thermal conductivity, and

ductility, C44300 copper nickel tubes perform better than C68700 in

work environments containing trace amounts of ammonia, requiring

good thermal conductivity efficiency, or requiring more expansion

and bending tube processing.

- ASTM B111 C68700 (aluminum brass) copper nickel tube is suitable for marine main

condensers, high-speed pump coolers, or estuarine power plants in

high flow rate, high turbulence, high sediment content, or high

suspended solids seawater working environments. At the same time,

in situations where ammonia is not present, higher requirements are

placed on the strength and hardness of the pipe material, and

general requirements are placed on thermal conductivity efficiency,

C68700 is more suitable than C44300. Under extremely harsh water

quality conditions, the erosion resistance life of C68700 is

usually better than that of C44300.

Summary:

ASTM B111 C44300 belongs to brass, specifically tin brass, more

commonly known as admiralty brass. The core advantage of C44300

copper nickel tubes lies in its good water corrosion resistance and

high cost performance. It is a classic choice between pure copper

and higher-grade alloys such as aluminum brass C68700 and

copper-nickel alloy C71500. However, it should be noted that

ASTM B111 C44300 copper nickel tube should be avoided in seawater

with high flow rate and high sand content, any environment where

ammonia may exist, and polluted seawater with high sulfide

content. Because C44300 is not as resistant to erosion

corrosion as aluminum brass (C68700) and copper-nickel alloy

(C71500/C70600) in seawater with high flow rate and high sand

content, its surface protective film is more easily damaged. At the

same time, it is difficult to maintain good strength in a working

environment containing ammonia or amines, such as the air cooling

area of a power plant, and stress corrosion cracking is very likely

to occur.

|