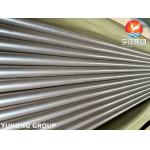

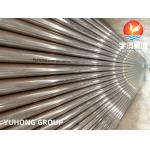

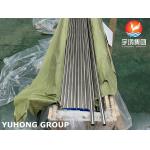

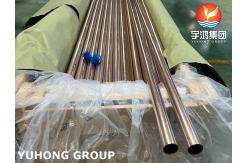

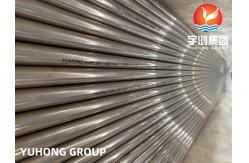

ASME SB111 C70600 Copper Nickel Tube for Condenser, Heat Exchanger

Application

ASME SB111 standard specifies the manufacturing process, material selection,

quality control and other aspects of white copper seamless tube in

detail, ensuring the reliability and stability of the product. At

the same time, the standard also emphasizes the corrosion

resistance of the product, and evaluates the corrosion resistance

of seamless tubes in different environments through a series of

strict test methods.

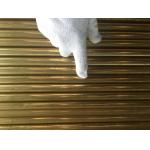

ASME SB111/ASTM B111 C70600 copper nickel tube is mainly composed of copper, nickel, iron and

manganese. Among them, the nickel content is about 9.0%-11.0%, the

iron content is between 1.0%-1.8%, the manganese content does not

exceed 1.0%, the zinc content does not exceed 1.0%, and the lead

content does not exceed 0.05%. Other elements such as phosphorus

and carbon also have strict content limits.

ASME SB111 C70600 Copper Nickel Tube Chemical Composition

| UNS NO. | ASME SB111 C70600 Copper Nickel Tube CHEMICAL COMPOSITION % |

|---|

| CU | NI | FE | ZI | MN | PH |

|---|

| C70600 | REM | 9.0-11.0 | 1.0-1.8 | 1.0 | 1.0 | --- |

ASME SB111/ASTM B111 C70600 Copper Nickel Tube Mechanical

properties:

- Tensile strength: The tensile strength of ASME SB111 C70600 copper nickel tube is

usually between 275MPa and 550MPa, depending on its heat treatment

state and processing method. Higher tensile strength means that the

alloy can resist breaking at a higher maximum stress when subjected

to tensile force, so it is suitable for environments with high

pressure.

- Yield strength: Yield strength is the maximum stress that a material can withstand

before plastic deformation occurs. The yield strength of ASME SB111

C70600 copper nickel tube is usually between 105MPa and 350MPa,

which is also affected by heat treatment and processing methods.

This property ensures the stability of the material when subjected

to stress.

- Elongation: The elongation of ASME SB111 C70600 copper nickel tube is generally

between 20% and 40% (some say about 30%), showing good plasticity.

This means that the alloy can undergo large plastic deformation

without breaking when subjected to external force, and is suitable

for cold working and shape change.

- Hardness: The Vickers hardness of ASME SB111 C70600 copper nickel tube is

usually between 160HV and 210HV, indicating that it has good wear

resistance and scratch resistance. Under the same conditions, the

Brinell hardness of C70600 copper nickel tube is about 80HB to

150HB (some say about 150HB), which ensures its long-term stability

in a strong wear environment.

ASME SB111 C70600 Copper Nickel Tube Tensile Requirements

| UNS NO. | Temper Designation | Tensile Strength min, ksi | Yield Strength min, ksi |

|---|

| Code | Name |

|---|

C70600, C70620 | O60 | Annealed | 40 | 15 |

C70600, C70620 | H55 | Light-drawn | 45 | 35 |

ASME SB111 C70600 Copper Nickel Tube Application:

- Marine engineering: C70600 copper nickel tube has excellent corrosion resistance in

seawater environment and is suitable for manufacturing key

components of seawater desalination equipment. It is also widely

used in ship components such as pipelines, cooling systems,

seawater pumps, etc. These components need to operate in seawater

environment for a long time. The seawater corrosion resistance of

C70600 copper alloy ensures its long-term stability and

reliability.

- Petroleum industry: Reactors, heat exchangers, evaporators and other equipment need to

withstand high temperature, high pressure and highly corrosive

media in the petrochemical production process. The excellent

properties of C70600 copper nickel tube make it an ideal material

for manufacturing these equipment; in corrosive media and high

temperature and high pressure environments, C70600 copper nickel

tube can be widely used in such as pipelines, valves and pump

bodies, relying on stable performance to ensure the normal

operation of petrochemical equipment.

- Aerospace: Aircraft engine parts such as turbine blades and combustion

chambers need to operate in extreme high temperature and high

pressure environments. The high temperature strength and corrosion

resistance of C70600 copper nickel tube make it suitable for such

applications. At the same time, the light weight, high strength and

good corrosion resistance of C70600 copper nickel tube make it an

ideal material for manufacturing satellite components.

- Food processing field: Such as brewing equipment, milk heaters, juice blenders and ice

makers, the corrosion resistance and hygienic properties of C70600

copper nickel tube meet food safety and hygiene requirements.

Summary:

ASTM B111 C70600 (90-10 Cu-Ni) belongs to copper-nickel alloy

(Cu-Ni), commonly known as 90-10 white copper. Thanks to the

synergistic effect of nickel and iron, C70600 copper nickel tube

can withstand uniform corrosion, pitting corrosion and crevice

corrosion, and has excellent and comprehensive seawater corrosion

resistance, which enables it to quickly adapt to occasions with

high seawater flow rates. At the same time, C70600's resistance to

ammonia stress corrosion cracking is far better than brass, and it

has good thermal conductivity, strength and machinability. Its

performance in all aspects is very close to C71500, but the cost is

significantly lower, so the cost performance is relatively better,

and an excellent balance is achieved between performance and cost.