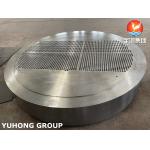

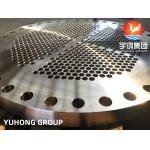

ALLOY STEEL FORGINGS SA336 F5N TUBESHEET HEAT EXCHANGER PARTS The SA336 F5N material is a type of forged alloy steel typically

used in high-temperature and pressure applications, such as in

boilers, pressure vessels, or heat exchangers.A tubesheet is a

thick plate that contains holes to hold the tubes of a heat

exchanger or boiler. It serves as a critical component in ensuring

the integrity and efficiency of these systems, by keeping the tubes

fixed in place while allowing for the transfer of heat. Key points about ASME SA336:Material Composition: The ASME SA336 specification covers several grades of alloy steel used in high-temperature applications. Some of the most commonly

used grades under this specification include: - Grade F1: Carbon-Manganese-Silicon alloy.

- Grade F5: Chromium-Vanadium alloy.

- Grade F9: Chromium-Molybdenum-Vanadium alloy.

- Grade F11: Chromium-Molybdenum alloy.

- Grade F22: Chromium-Molybdenum alloy (more resistant to oxidation).

These alloys are specifically designed to resist heat, pressure,

and corrosion at elevated temperatures.

Common Grades:- SA336 F5N: A common grade in the SA336 standard, used in heat exchangers,

pressure vessels, and other high-temperature applications.

- SA336 F9: Known for its improved resistance to oxidation and creep at

higher temperatures, commonly used in more demanding power

generation environments.

ASME SA336 Grade Table| Grade | Alloy Composition | Typical Applications | Properties |

|---|

| F1 | Carbon-Manganese-Silicon | Pressure vessels, steam boilers, and heat exchangers at temperatures up to 900°F (480°C). | Moderate strength, good toughness and weldability at high

temperatures. | | F5 | Chromium-Vanadium (0.5–0.75% Cr, 0.1–0.2% V) | Steam turbines, heat exchangers, gas turbines, and high-temperature piping systems. | Improved resistance to creep, oxidation, and high-temperature

fatigue. | | F5B | Chromium-Vanadium | High-temperature structural components. | Similar to F5 but with enhanced properties for better

high-temperature performance. | | F9 | Chromium-Molybdenum-Vanadium (0.5–0.6% Cr, 0.25–0.35% Mo, 0.1–0.15% V) | Power plant pressure vessels, heat exchangers, boilers, turbines, and pipelines. | Higher creep strength and oxidation resistance, suitable for

higher-temperature applications (up to 1050°F or 565°C). | | F11 | Chromium-Molybdenum (1–1.5% Cr, 0.5–0.8% Mo) | High-temperature piping, boilers, pressure vessels, and heat exchangers. | Offers good strength and resistance to thermal fatigue and

corrosion. Commonly used in fossil-fuel power plants and refineries. | | F22 | Chromium-Molybdenum (2.25% Cr, 1% Mo) | High-temperature service, superheaters, reheater tubes, steam turbines. | Excellent high-temperature strength and resistance to creep,

oxidation, and corrosion. Common in fossil-fuel plants and chemical refineries. | | F91 | Chromium-Molybdenum-Vanadium (9% Cr, 1% Mo, 0.2% V) | Superheater tubes, boilers, steam turbines in ultra-supercritical plants, power plant piping. | Excellent resistance to high-temperature oxidation, corrosion, and

creep. Used in high-stress, high-temperature applications. | | F92 | Chromium-Molybdenum-Vanadium (9% Cr, 1% Mo, 0.2% V) | Boilers, pressure vessels, and heat exchangers. | Very high creep resistance and excellent weldability at elevated

temperatures, widely used in fossil fuel and nuclear power plants. |

|