ASTM A106 A333 A179 A210, P5 P11 P22 P9, Longitudinal Finned Tube

|

|

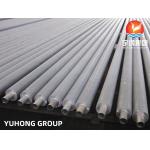

LONGITUDINAL FINNED TUBE

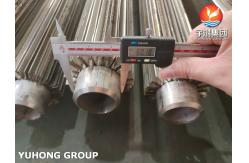

Longitudinal finned tubes are produced by welding fins with resistors along the length of the tube. The fins are first formed into a U-shaped channel, allowing each U-shaped leg to form a fin. The channel is cut to the appropriate length and then welded in place along the length of the tube and resistors. The channels are welded in pairs, at opposite poles, so the number of fins specified must be a multiple of four. For a given tube or tube size, the required heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height and number of fins.

LONGITUDINAL FINNED TUBE MATERIAL:

2.Stainless steel 3.Alloy steel 4.Brass

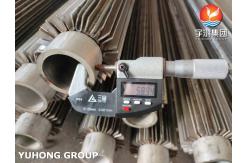

Quality Control for LONGITUDINAL FINNED TUBE

Application Of LONGITUDINAL FIN TUBE

steel, petroleum, chemical industy,machinery, shipbulding, power station, hospital and food industy.

|

|||||||||||||||||||||||||||||||||||||||||

| Product Tags: P9 Carbon Steel Fin Tube P22 Carbon Steel Fin Tube P11 Carbon Steel Fin Tube | |||||||||||||||||||||||||||||||||||||||||

|

ASTM A213 T9 Alloy Steel Studded Fin Tube With Alloy / Stainless Steel Studs For Boiler Or Heater |

|

ASTM A213 T9 Studded Alloy Steel Seamless Tube For Air Heaters And Economizers |

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Nail Head Tube Studded Tube For Petrochemical Industry |

|

ASME SA210 Gr A1 Seamless Tube Al1060 Aluminum Fin Embedded G Type Fin Tube |