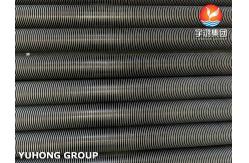

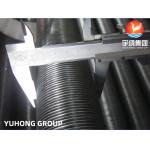

High Frequency Welding ASTM A312 TP316L Stainless Steel Fin Pipe For Furnace

|

Detailed Product Description

High-Frequency Welding ASTM A312 TP316L Stainless Steel Fin Pipe for Furnace Applications

ASTM A312 TP316L stainless steel finned pipes are widely used in furnaces and heat-intensive environments where superior corrosion resistance and thermal conductivity are required. The high-frequency welding process ensures a strong bond between the fins and the base tube, optimizing heat transfer efficiency and durability under harsh conditions. 1. Material SpecificationsBase Tube Material:

Fin Material:

2. Chemical Composition of Base Tube (ASTM A312 TP316L)

3. Mechanical Properties of Base Tube (ASTM A312 TP316L)

4. Key Features of High-Frequency Welded Fins

5. Applications

6. Advantages

|

||||||||||||||||||||||||||||

| Product Tags: ASTM A312 Fin Pipe High Frequency Welding Fin Pipe Furnace Fin Pipe |

Related Products

|

ASTM A213 T9 Studded Alloy Steel Seamless Tube For Air Heaters And Economizers |

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Nail Head Tube Studded Tube For Petrochemical Industry |

|

ASME SA210 Gr A1 Seamless Tube Al1060 Aluminum Fin Embedded G Type Fin Tube |

|

Embedded G Type Finned Tube ASME SA210 Gr.A1 Seamless Tube With Aluminum Al1060 |

Email to this supplier