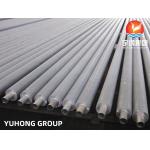

ASTM A213 T9 Alloy Steel Studded Fin Pipe with 13Cr Studs for

Radiant Coil Applications

Studded fin pipes are widely used in radiant coils for

high-temperature and high-pressure environments such as furnaces,

heaters, and boilers. ASTM A213 T9 alloy steel with 13% chromium (13Cr) studs ensures excellent mechanical strength, thermal efficiency, and

resistance to corrosion and oxidation, making it ideal for

demanding applications.

1. Material Specification Base Tube Material:- Standard: ASTM A213

- Grade: T9 Alloy Steel

- Type: Seamless ferritic alloy steel

- Applications: Used in high-temperature services, including heat exchangers and

boiler systems.

Stud Material:- Material: 13Cr (13% Chromium)

- Purpose: Improves heat transfer and resists oxidation and corrosion at

elevated temperatures.

2. Chemical Composition ASTM A213 T9 Base Tube:| BASE TUBE ASTM A213 T9 FIN PIPE Chemical Composition | | Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Molybdenum (Mo) | ASTM A213 T9 | 0.08 – 0.18 | 0.30 – 0.60 | ≤ 0.025 | ≤ 0.025 | 0.50 – 1.00 | 8.00 – 10.00 | 0.90 – 1.10 |

13Cr Studs:| STUDS 13Cr Chemical Composition | | Element | Carbon (C) | Manganese (Mn) | Chromium (Cr) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | | 13Cr Studs | ≤ 0.20 | ≤ 1.00 | 12.00 – 14.00 | ≤ 1.00 | ≤ 0.030 | ≤ 0.030 |

3. Mechanical Properties | BASE TUBE ASTM A213 T9 FIN PIPE Mechanical Properties | | Property | Tensile Strength | Yield Strength | Elongation | Hardness | | ASTM A213 T9 | ≥ 415 MPa | ≥ 205 MPa | ≥ 20% | ≤ 163 HB |

| STUDS 13Cr Mechanical Properties | | Property | Tensile Strength | Yield Strength | Elongation | Hardness | | 13Cr Studs | ≥ 485 MPa | ≥ 275 MPa | ≥ 15% | ≤ 217 HB |

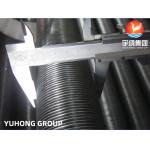

4. Features of Studded Fin Pipe Enhanced Heat Transfer: - The 13Cr studs provide additional surface area, significantly

improving heat transfer efficiency.

- Suitable for radiant sections in furnaces where high thermal

conductivity is crucial.

High-Temperature Resistance: - ASTM A213 T9 alloy steel withstands elevated temperatures up to

650°C.

- 13Cr studs resist oxidation and scaling, even in aggressive

environments.

Corrosion Resistance: - Chromium content in the base tube and studs enhances resistance to

corrosion in harsh environments, including exposure to flue gases

and combustion byproducts.

Durability: - Strong mechanical bonding between the base tube and studs ensures

long-term performance under thermal cycling and vibration.

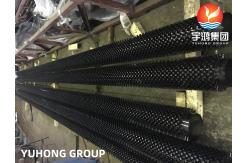

5. Applications Radiant Coils in Furnaces and Heaters: - Used in radiant sections to absorb heat from combustion gases and

transfer it to process fluids.

Boiler Systems: - Ideal for water tube boilers in power plants and refineries.

Petrochemical and Refining Industries: - Commonly used in process heaters, reformers, and cracking furnaces.

High-Temperature Heat Exchangers: - Suitable for heat recovery applications in industrial processes.

6. Advantages - Energy Efficiency: Improves thermal efficiency by maximizing heat transfer in

radiant sections.

- Longevity: Combines high-temperature resistance and corrosion resistance for

long-term durability.

- Cost-Effective: Reduces downtime and maintenance costs by providing a reliable

and robust heat exchange solution.

- Versatility: Suitable for various high-temperature industrial processes.

|