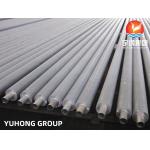

ASTM A210 / ASME SA210 Gr. A1 Carbon Steel Fin Tube with Aluminum

Fin (G Type) is a specific type of finned tube used in heat exchangers,

boilers, and condensers. It combines the strength and thermal

conductivity properties of carbon steel with the corrosion

resistance and lightweight nature of aluminum fins. Here’s a

breakdown of its features, applications, and advantages: Key Specifications:Material: - ASTM A210 / ASME SA210 Gr. A1: This refers to a seamless carbon steel tube, which is commonly

used in high-pressure and high-temperature applications, such as

boilers, heat exchangers, and steam systems. This grade has good

tensile strength, weldability, and ductility, making it suitable

for heat transfer applications.

- Aluminum Fins: Aluminum is commonly used for finning because it has excellent

thermal conductivity and is lightweight. The fins are typically

helically wound or attached through mechanical bonding or welding

to the carbon steel tube. The aluminum enhances the heat transfer

efficiency of the tube.

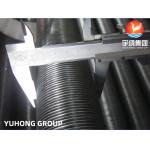

Fin Type (G Type): - G Type refers to a specific profile or design of the fins that are

attached to the tube. These fins may be extruded, helically wound, or stamped. The "G" designation typically indicates a particular geometry,

such as the fin pitch, height, or shape, optimized for particular

heat transfer applications. The fin geometry plays a key role in

increasing the surface area for efficient heat exchange.

Applications:Heat Exchangers: These finned tubes are widely used in various types of heat

exchangers, where heat needs to be transferred efficiently between

two fluids (e.g., in power generation, chemical processing, HVAC

systems). Boilers: The carbon steel tube with aluminum fins is ideal for use in

boiler systems, particularly for economizers, superheaters, and air

heaters, where the tube must withstand high temperatures while

promoting heat exchange. Condensers: Used in condensers for cooling purposes, where the fin tubes help

in improving heat dissipation and efficiency by transferring heat

from the vapor phase to the cooling fluid. Air Coolers & Radiators: Aluminum fins improve the overall cooling efficiency in air

coolers and radiators used in various industrial and automotive

applications. Power Generation: These tubes are also used in power plants for applications where

high-efficiency heat transfer is critical, such as in feedwater

heaters or steam generators.

Advantages:Improved Heat Transfer Efficiency: The combination of carbon steel tubing and aluminum fins

maximizes heat exchange between the fluid inside the tube and the

external environment. Aluminum has a high thermal conductivity,

which improves overall heat transfer efficiency. Corrosion Resistance: While the carbon steel tube provides structural strength, the

aluminum fins offer resistance to corrosion, especially in

atmospheres with moderate humidity and corrosive environments. Cost-Effective: Aluminum fins are relatively inexpensive compared to other

materials, which can help reduce manufacturing costs while still

maintaining good performance in terms of heat transfer and

durability. Lightweight: The use of aluminum fins makes the finned tube system lighter

compared to finned tubes with other materials, which is beneficial

in applications where weight is a critical factor (e.g., in

automotive applications or in areas where transportability is

important). Durability and Strength: The carbon steel tube provides strength and durability, which is

particularly useful in high-pressure or high-temperature

applications, ensuring the system’s longevity.

Typical Manufacturing Process:- Tube Fabrication: The tube is made from seamless carbon steel (ASTM A210 Gr. A1)

and is typically manufactured by extrusion or seamless drawing

processes.

- Finning: The aluminum fins are either extruded or mechanically bonded to the steel tube. In the "G type" design, the fins might be

formed in specific patterns, like helical or spiral winding, to

maximize heat dissipation.

|