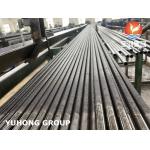

ASTM A213 T9 ALLOY STEEL STUDDED FIN PIPE, 13CR STUD FOR FURNACE1. ASTM A213 T9 Alloy Steel- Material Standard: ASTM A213 T9 is a specification for seamless ferritic and

austenitic alloy steel tubes. It is commonly used for boiler,

superheater, and heat exchanger tubes, especially in applications

with elevated temperatures and pressures.

- Grade T9: This is a chromium-molybdenum alloy steel (9% Chromium and 1%

Molybdenum), which provides excellent resistance to oxidation,

high-temperature strength, and creep resistance. These

characteristics make T9 suitable for extreme conditions, such as

those found in furnaces and boilers.

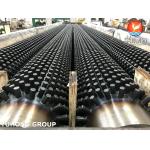

2. Studded Fin Pipe- Purpose: A studded fin pipe has metal studs welded onto the pipe’s outer

surface. These studs act as fins, increasing the pipe’s surface

area to enhance heat transfer. This design is especially useful in

applications where there is a need for high efficiency in heat

transfer between the pipe and surrounding environment.

- Application in Furnaces: Studded pipes are used in furnaces where the increased surface

area allows for more effective heat transfer from the furnace to

the pipe, optimizing heating and energy efficiency.

3. 13Cr Studs- Material: The "13Cr" refers to 13% chromium alloy studs, a stainless steel

variant known for its corrosion resistance and durability at high

temperatures. 13Cr stainless steel is typically resistant to

oxidation and scaling, especially in elevated-temperature

environments.

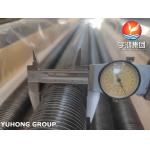

- Stud Welding: The 13Cr studs are welded onto the T9 alloy steel pipe, providing

a strong bond that withstands high-temperature cycles without

detaching. The choice of 13Cr studs is ideal for furnace

applications where both heat resistance and durability are

critical.

- Enhanced Heat Transfer: The studs serve to extend the pipe’s effective surface area,

enhancing heat exchange and improving the overall efficiency of the

system. The durable connection also helps maintain efficiency over

extended periods in demanding conditions.

Advantages of ASTM A213 T9 Studded Fin Pipe with 13Cr Studs- High Temperature and Pressure Resistance: ASTM A213 T9 alloy steel is designed to perform in harsh

conditions, making it suitable for furnaces where high temperatures

and pressures are common.

- Improved Heat Transfer: The studded design maximizes surface area, leading to efficient

heat transfer, which is critical in furnace applications.

- Corrosion and Oxidation Resistance: The chromium content in both T9 alloy steel and 13Cr studs offers

excellent resistance to corrosion, oxidation, and scaling at high

temperatures.

- Durability and Mechanical Strength: The alloy steel pipe and high-strength studs ensure longevity and

minimal maintenance needs, even in environments with fluctuating

thermal cycles.

Applications 1. Furnaces in Petrochemical and Refinery Industries- Role: In petrochemical plants, furnaces are essential for heating raw

materials to start chemical reactions. The studded fin design

enhances the surface area for heat transfer, making these pipes

highly effective in maximizing energy use and controlling

temperature distribution.

- Benefit: The ASTM A213 T9 pipe's heat resistance and studded fins allow it

to handle intense heat while providing reliable and stable

performance. This stability is crucial in an industry where

precision and safety are always at the forefront.

2. Power Generation Boilers and Heat Exchangers- Role: These pipes are also commonly used in power plants, especially in

boiler systems where steam is generated at high temperatures. The

studded fins aid in transferring heat efficiently to the water,

enabling steady steam production.

- Benefit: For power plants aiming to operate efficiently and sustain high

output, the durability and heat transfer capabilities of the T9

studded fin pipes play an integral part in ensuring smooth,

efficient energy conversion processes.

3. Chemical Processing Furnaces- Role: Chemical processes often require carefully controlled heating to

ensure reactions occur as expected. The ASTM A213 T9 pipes, with

their chromium-molybdenum alloy, withstand intense heat and resist

corrosion in these high-demand environments.

- Benefit: Here, the high-temperature resistance and extended surface area

provided by the studded fins allow for precise temperature control,

reducing the risk of hot spots or temperature inconsistencies.

|