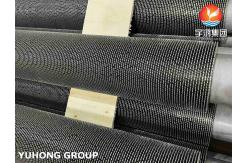

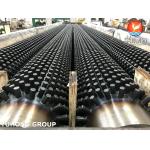

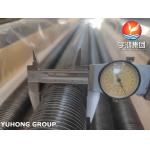

Serrated Finned Tube HFW Helical Spiral Serrated Fin Tube for Heat Exchangers

|

|

High Frequence Welded Fin Tube , HFW Helical Serrated Heat Exchanger Finned Tube

HFW (High Frequency Welded) serrated fin tubes are created by welding fins onto the surface of the tube. The design can be optimized for both air-to-liquid and liquid-to-liquid heat exchange scenarios. This welding method and serration in the fins creates turbulent flow, which ensures high structural integrity and the ability to withstand pressure and temperature variations. It has better heat transfer efficiency compared to smooth fins.

Please provide below fin tube details for quick quote: • Base tube standard, material • Base tube size • Fin material • Fin type • Fin diameter or height • Fin thickness • Fins per inch or fins per meter • Lenght of unfinned ends • Quantity

Fin Tube Specification

Material Grade

Advantages:

Specific Application Cases:

Operational Considerations:

Industries of Use:

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Helical Spiral Serrated Finned Tube HFW Serrated Finned Tube Heat Exchangers Serrated Finned Tube |

|

Studded Tube , ASTM A213 T9 / ASME SA213 T11 with 11Cr (SS 409) Studded Fin Tube ,Steam Reforming Furnace |

|

ASME SA179 , ASTM A179 Carbon Steel Low Finned Tube, for Air Cooler, cooling tower application |

|

Welded Helical Serrated Fin Tubes HFW Fin Tube For Per Heating Application |

|

ASME SA210 Gr.A1 Seamless Tube with Aluminum Al1060 Embedded G type Fin tube |

|

ASTM A179/ ASME SA179 Carbon Steel Seamless Tube with Aluminum 1060, Air Cooler, Extruded Fin Tube ,Embedded G Fin Tube |

|

ASTM A179 Carbon Steel Seamless Tube with Aluminum ASTM B221 6063 (1060), Extruded Fin Tube |