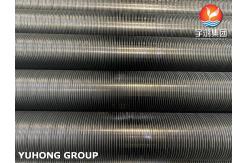

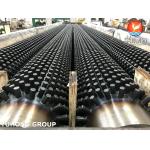

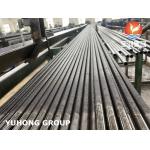

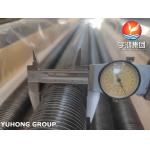

Customized High Frequency Welded / HFW Solid Finned Tube For Boiler Economizer

|

|

Carbon /Stainless/ Alloy Steel High Frequency Welded / HFW Solid Finned Tube

HFW / High-Frequency Welded finned tube. For HFW solid finned tubes, they are specialized tubes commonly used in applications such as boiler, heat exchangers and industrial heating systems. For welding technique of HFW finned tubes, they are produced by welding the edges of a strip (stainless steel, alloy steel, carbon steel), using high-frequency electrical currents to generate heat, which results in a solid weld. For fin attachment: Fins are attached to the tubes to enhance heat transfer surfaces. These fins can be integral (part of the tube) or attached post-manufacturing. Yuhong can also make the drawing according to clients' requirements.

Common Base Material of HWF solid finned tube HFW solid finned tube is usually made from carbon steel, stainless steel or alloys, each selected based on the required thermal properties and resistance to corrosion and pressure.

Design Considerations

Performance Features

Advantages of high-frequency welded finned tubes

Application of Finned Tube in Industries

|

||||||

| Product Tags: Boiler Economizer Finned Tube Customized Finned Tube HFW Solid Finned Tube |

|

Studded Tube , ASTM A213 T9 / ASME SA213 T11 with 11Cr (SS 409) Studded Fin Tube ,Steam Reforming Furnace |

|

ASME SA179 , ASTM A179 Carbon Steel Low Finned Tube, for Air Cooler, cooling tower application |

|

Welded Helical Serrated Fin Tubes HFW Fin Tube For Per Heating Application |

|

ASME SA210 Gr.A1 Seamless Tube with Aluminum Al1060 Embedded G type Fin tube |

|

ASTM A179/ ASME SA179 Carbon Steel Seamless Tube with Aluminum 1060, Air Cooler, Extruded Fin Tube ,Embedded G Fin Tube |

|

ASTM A179 Carbon Steel Seamless Tube with Aluminum ASTM B221 6063 (1060), Extruded Fin Tube |