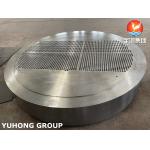

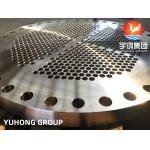

ASTM B171 Naval Brass C46400 Tube Sheet for Heat Exchanger

The material C46400, also known as naval brass, is a type of copper

alloy that typically contains copper, zinc, and a small amount of

tin. C46400 tubesheets are an excellent choice for

industries. It's known for its good corrosion resistance,

particularly in marine environments, and excellent strength and

durability. Their ability to perform well in challenging

environments makes them reliable for various applications,

especially in marine setting and also frequently used in heat

exchangers, condensers, and other marine and industrial

applications where resistance to corrosion is essential.

Chemical Composition | | Elements |

|---|

|

| (1) Cu + Sum of Named Elements 99.6% min. | | 59.0 | | 0.50 | | | | 62.0 | 0.20 | 1.0 | Rem | 0.10 |

Physical Properties | 1650 | | 1630 | | 0.304 | | 8.41 | | 26 | | 67 | | 11.8 | | 0.09 | | 15000 | | 5600 |

Mechanical Properties |

| * Measured at room temperature, 68°F (20°C). | | 1/4 Hard | H01 | 70 Typ | | 17 Typ | 75 Typ | 68 Typ | 43 Typ | | | 0.04 | | | As Hot Rolled | M20 | 55 Typ | 25 Typ | 50 Typ | 55 Typ | 55 Typ | 40 Typ | | | 1 | | | Light Anneal | O50 | 60 Typ | 28 Typ | 45 Typ | 58 Typ | 56 Typ | 41 Typ | | | 0.25 | | | Light Anneal | O50 | 62 Typ | 30 Typ | 40 Typ | 60 Typ | 57 Typ | 41 Typ | | | 0.04 | | | Soft Anneal | O60 | 58 Typ | 25 Typ | 49 Typ | 56 Typ | 55 Typ | 40 Typ | | | 0.25 | | | Soft Anneal | O60 | 58 Typ | | 49 Typ | | | | | 40 Typ | 0.24 | | | Soft Anneal | O60 | 56 Typ | 25 Typ | 47 Typ | | | | 60 Typ | 40 Typ | 2 | | | Soft Anneal | O60 | 57 Typ | 25 Typ | 47 Typ | | | | 60 Typ | 40 Typ | 1 | | | Soft Anneal | O60 | 58 Typ | 27 Typ | 45 Typ | | | | 60 Typ | 40 Typ | 0.24 | | | 1/4 Hard | H01 | 69 Typ | | 27 Typ | | | | 50 Typ | 43 Typ | 1 | 8 | | 1/4 Hard | H01 | 67 Typ | 40 Typ | 35 Typ | | | | 50 Typ | 43 Typ | 2 | 8 | | 1/4 Hard | H01 | 70 Typ | 48 Typ | 25 Typ | | | | 50 Typ | 43 Typ | 0.24 | 10 | | 1/4 Hard | H01 | 70 Typ | 58 Typ | 17 Typ | | | | | 43 Typ | 0.04 | | | Light Anneal | O50 | 62 Typ | 30 Typ | 40 Typ | | | | | 41 Typ | 0.04 | | | Light Anneal | O50 | 63 Typ | 30 Typ | 40 Typ | | | | 55 Typ | 42 Typ | 0.24 | | | Light Anneal | O50 | 60 Typ | 28 Typ | 45 Typ | | | | | 41 Typ | 0.24 | | | Light Anneal | O50 | 62 Typ | 28 Typ | 43 Typ | | | | 55 Typ | 42 Typ | 2 | | | Light Anneal | O50 | 63 Typ | 30 Typ | 40 Typ | | | | 55 Typ | 42 Typ | 1 | | | 1/2 Hard | H02 | 75 Typ | | 20 Typ | 82 Typ | | 44 Typ | | | 1 | 20 | | 1/2 Hard | H02 | 80 Typ | 57 Typ | 20 Typ | 85 Typ | | 45 Typ | | | 0.25 | 20 | | 1/4 Hard | H01 | 70 Typ | 48 Typ | 25 Typ | 80 Typ | | 43 Typ | | | 0.25 | 10 | | 1/4 Hard | H01 | 69 Typ | 46 Typ | 27 Typ | 78 Typ | | 43 Typ | | | 1 | 8 | | 1/4 Hard | H01 | 67 Typ | 40 Typ | 35 Typ | 75 Typ | | 43 Typ | | | 2 | 8 | | Light Anneal | O50 | 63 Typ | 30 Typ | 40 Typ | 60 Typ | | 42 Typ | | | 1 | | | Light Anneal | O50 | 62 Typ | 28 Typ | 43 Typ | 60 Typ | | 42 Typ | | | 2 | | | Light Anneal | O50 | 63 Typ | 30 Typ | 40 Typ | 60 Typ | | 42 Typ | | | 0.25 | | | Soft Anneal | O60 | 58 Typ | 27 Typ | 45 Typ | 56 Typ | | 40 Typ | | | 0.25 | | | Soft Anneal | O60 | 56 Typ | 25 Typ | 47 Typ | 55 Typ | | 40 Typ | | | 2 | | | Soft Anneal | O60 | 57 Typ | 25 Typ | 47 Typ | 55 Typ | | 40 Typ | | | 1 | | | 1/2 Hard | H02 | 75 Typ | | 20 Typ | | | | 45 Typ | 44 Typ | 1 | 20 | | 1/2 Hard | H02 | 80 Typ | 57 Typ | 20 Typ | | | | 45 Typ | 45 Typ | 0.24 | 20 | | Hard Drawn | H80 | 88 Typ | | 18 Typ | 95 Typ | | | | | | 35 |

Material Grades of Tubesheet | Type of materials | Technical requirements according to | | Duplex Stainless Steel | ASTM/ASME SA182 F44, F45, F51, F53, F55, F60, F61 | | Stainless Steel | ASTM/ASME SA182 F304,304L,F316,316L, F310, F317L, F321, F347 | | Carbon Steel | ASTM/ASME A105, A350 LF1, LF2, A266, A694, A765 Gr.2 | | Alloy Steel | ASTM/ASME SA182 F1, F5, F9, F11, F12, F22, F51, A350-LF3 | | Titanium | ASTM/ASME SB381, Gr.1, Gr.2, Gr.5, Gr.7, Gr.12, Gr.16 | | Copper Nickel | ASTM/ASME SB151, UNS 70600(Cu-Ni 90/10), 71500(Cu-Ni 70/30) | | Brass, Al-brass | ASTM/ASME SB152 UNS C10100, C10200,C10300,C10800,C12200 | | Nickel Alloys | ASTM/ASME SB169,SB171, SB564, UNS 2200, UNS 4400, UNS 8825

UNS 6600, UNS 6601, UNS 6625 | | Alloy 20 | ASTM/ASME SB472 UNS 8020 | | Hastelloy | ASTM/ASME SB564, UNS10276 ( C 276 ) | | Claded materials | ASTM/ASME SB898, SB263, SB264 or closer

explosion cladding, making materials of 2 in 1 or 3 in 1. | Titanium- Steel, Nickel-Steel,Titanium- Copper,

Stainless Steel- Carbon Steel, Alloys- Steel etc. |

Application

1. Heat Exchangers

2. Boilers

3. Condensers

4. Reactors

5. Oil and Gas Industry

6. Air Conditioning and Refrigeration

7. Pressure Vessels

|