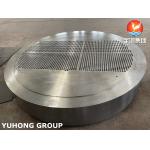

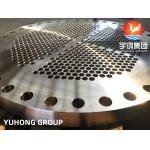

ASTM B171 C46400 Stationary Tubesheet Essential Component For Heat Exchangers

|

|

ASTM B171 C46400 Stationary Tubesheet Used In Heat Exchanger ASTM B171 is a standard specification for seamless copper and copper alloy tubing. It includes various grades of copper and copper alloys suitable for a variety of applications, including heat exchangers.

C46400 is a specific alloy grade mentioned in this context. This alloy is also known as "Copper Alloy 46400" or "C46400 Copper Nickel Zinc". It is an alloy that combines copper with nickel (about 28-30% by weight), zinc (about 15-16% by weight), and small amounts of other elements like iron, manganese, and aluminum.

When used in heat exchangers, the properties of C46400 make it particularly suitable for applications where high temperatures and pressures are involved, as well as where corrosion resistance is critical. Its high strength, excellent thermal conductivity, and resistance to corrosion in many environments make it ideal for use in stationary tubesheets within heat exchangers. These tubesheets typically provide a mounting surface for the tubes in the heat exchanger and can be exposed to high temperatures and corrosive fluids.

In heat exchanger applications, C46400 is often utilized for its ability to maintain integrity under harsh conditions. Its combination of mechanical strength and corrosion resistance allows it to handle the stresses of continuous operation in industries such as chemical processing, oil refining, and power generation, where reliable performance and durability are paramount.

However, it's important to note that while C46400 is robust, proper maintenance, inspection, and replacement schedules should be implemented to ensure optimal performance and safety over the life of the heat exchanger system. Equivalent specification

Chemical composition

Tube sheets are key components of various heat exchangers and

shell-and-tube vessels. Its main purpose is to provide support and

sealing to the tube bundle. Within cylindrical or rectangular

tubes, there are different types of tubesheets, each type designed

for a specific application. Here are some common segment types and

their detailed descriptions: 1.Fixed tube sheet: Description: The fixed tube sheet is fixed in

the shell of the heat exchanger and welded or welded into the hole

of the fixed tube sheet. They will not move relative to the tube

sheet and the expansion between the tubes and the shell is very

small. 2. Floating tube sheet 3. U-shaped tube bundle 4. Floating head tube plate 5.Fixed tubesheet (with expansion joint description) The characteristics of fixed tube plate heat exchanger are: 1. The bypass seepage is small; 2. Forgings are used less and cost is low; 3. No internal leakage; 4. The heat transfer area is 20% to 30% larger than that of the

floating head heat exchanger. The disadvantages of fixed tube plate heat exchangers are: 1. The temperature difference between the shell and the pipe wall

is large. When t ≥ 50°C, an expansion joint must be installed on

the shell; 2. Temperature difference force is easily generated, and

temperature difference stress is easily generated between the tube

plate and the tube head, causing damage; 3. The shell side cannot be cleaned mechanically; 4. After the pipes are corroded, they will be scrapped together

with the casing, and the equipment life will be short. |

||||||||||||||||||||||||

| Product Tags: ASTM B171 Stationary Tubesheet C46400 Stationary Tubesheet Heat Exchangers Stationary Tubesheet |

|

Normalized Carbon Steel Tubesheet Sa516 Gr.70n Heat Exchanger Component |

|

ASTM A182 Stainless Steel Baffle And Tubesheet For Heat Exchanger |

|

ASME SA516 Gr.70N Stationary Tubesheet Used In Heat Exchanger |

|

High Strength Steel Baffle And Tube Sheet Used In Heat Exchanger / Boiler / Air Conditing |

|

EN10028 1.4541 Stainless Steel Tube Sheet For Floating Head Exchanger Shell Heat Exchanger |

|

ASTM A182 F316L Stainless Steel Tubesheet For Heat Exchanger |