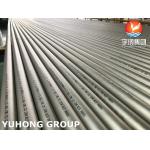

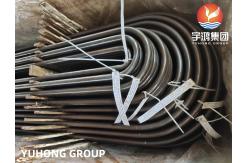

U Shape ASTM A179 Carbon Steel Seamless Tube For Heat Exchanger,

Boiler

Introduction

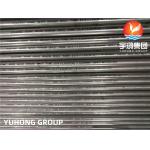

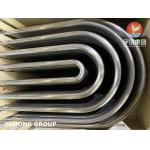

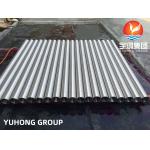

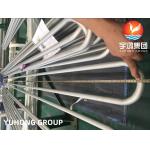

A179 U-bend tubes are seamless cold-drawn low-carbon steel tubes

designed for heat transfer applications. Manufactured to ASTM A179

standards, these tubes feature a U-bend shape that enhances their

suitability for use in heat exchangers, condensers, and boilers.

The seamless construction and precise bending process ensure

excellent thermal conductivity and structural integrity.

Advantages

- High Thermal Conductivity: Excellent for efficient heat transfer, crucial in many industrial

processes.

- Corrosion Resistance: Good resistance to corrosion extends the lifespan and reliability

of the tubes.

- Mechanical Strength: High tensile strength and durability ensure performance under

stress.

- Precision and Uniformity: Seamless construction provides uniform wall thickness and smooth

internal surfaces, enhancing fluid flow and heat transfer

efficiency.

- Space Efficiency: U-bend configuration allows for more compact designs in heat

exchanger systems.

- Cost-Effective: Offers a balance of performance and cost, making them a popular

choice across various industries.

Chemical Composition:

- Carbon: 0.06% - 0.18%

- Manganese: 0.27% - 0.63%

- Phosphorus: ≤ 0.035%

- Sulfur: ≤ 0.035%

Mechanical Properties:

- Tensile Strength: Minimum 325 MPa (47,000 psi)

- Yield Strength: Minimum 180 MPa (26,000 psi)

- Elongation: Minimum 35% in 2 inches (50 mm)

Applications

- Heat Exchangers: Utilized in shell and tube heat exchangers for efficient heat

transfer between fluids.

- Condensers: Essential in power plants and HVAC systems for condensing steam

into water.

- Boilers: Used in boiler systems for generating steam and heating

applications.

- Chemical Processing: Employed in reactors and distillation columns for precise

temperature control.

- Oil and Gas Industry: Used in refineries and petrochemical plants for various heating

and cooling processes.

- Power Generation: Integral in power plants for waste heat recovery and other

thermal processes.

A179 U-bend tubes are crucial components in various industries

requiring efficient heat transfer. Their high thermal conductivity,

corrosion resistance, and mechanical properties make them a

preferred choice for many applications, including heat exchangers,

condensers, boilers, and chemical processing equipment.