ASTM EN Heat Exchanger Parts Tube sheet Botton Head Shell

|

Detailed Product Description

|

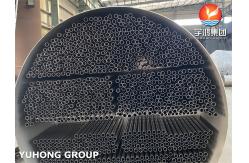

ASTM Heat Exchanger Parts Tube sheet

A tube sheet is a component of a heat exchanger that is used to

support and hold the tubes in place. It is typically made of a

metal material, such as carbon steel or stainless steel, and is

designed to provide a secure and leak-proof connection between the

tubes and the shell of the heat exchanger. The tube sheet is usually a thick, flat plate with holes drilled or

punched into it to accommodate the tubes. The size and arrangement

of the holes will depend on the specific design and requirements of

the heat exchanger. The tubes are inserted into the holes and then

expanded or welded to create a tight seal. In addition to supporting the tubes, the tube sheet also serves to

separate the fluid flowing through the tubes from the fluid flowing

in the shell of the heat exchanger. This helps to prevent any

mixing or contamination of the fluids. The tube sheet is a critical component of a heat exchanger and

needs to be carefully designed and manufactured to ensure proper

performance and reliability. It must be able to withstand the high

temperatures and pressures that are often encountered in heat

exchanger applications. The material selection, hole design, and

manufacturing processes all play a role in ensuring the tube sheet

meets these requirements. Tube sheet is an essential part of a heat exchanger, providing

support, sealing, and fluid separation functions. It is a key

factor in determining the efficiency and effectiveness of the heat

transfer process in the heat exchanger. Heat Exchanger Shell A heat exchanger shell is the outer casing or enclosure of a heat

exchanger. It is designed to contain the heat transfer fluid and

provide a protective barrier between the hot and cold fluids being

exchanged. The shell is typically made of metal and is designed to

withstand high temperatures and pressure. Inside the shell, there

are tubes or channels through which the hot and cold fluids flow,

allowing for efficient heat transfer between the two fluids. The

design and construction of the shell are crucial for the overall

performance and efficiency of the heat exchanger. Heat Echanger Bottom Head The bottom head of a heat exchanger is the component that seals off

the bottom of the heat exchanger shell. It is typically a flat or

dished plate that is welded or bolted onto the bottom of the shell

to contain the heat transfer fluids and prevent leakage. The bottom

head is an important part of the heat exchanger as it helps to

maintain the pressure and temperature of the fluids within the

shell. It is typically made of a material that is compatible with

the heat transfer fluids being used in the exchanger, such as

carbon steel, stainless steel, or titanium. The bottom head may

also have openings for the inlet and outlet connections for the

heat transfer fluids. Tube sheets are used in various applications, including: 1. Heat exchangers: Tube sheets are an integral part of heat exchangers, which are used to transfer heat between two fluids. The tube sheet holds the tubes in place and provides a seal between the two fluid streams. 2. Boilers: Tube sheets are used in boilers to support the tubes and provide a seal between the combustion gases and the water/steam. 3. Condensers: Tube sheets are used in condensers, which are used to condense vapors into liquids. The tube sheet holds the tubes in place and allows for efficient heat transfer. 4. Shell and tube heat exchangers: Tube sheets are used to support the tubes in shell and tube heat exchangers, which are commonly used in industries such as oil and gas, chemical, and power generation. 5. Pressure vessels: Tube sheets are used in pressure vessels, which are containers designed to hold gases or liquids at a pressure significantly different from the ambient pressure. The tube sheet provides structural support and helps maintain the integrity of the vessel. 6. Reactors: Tube sheets are used in reactors, which are vessels used to carry out chemical reactions. The tube sheet holds the tubes in place and provides a seal between the reactants and the surroundings. 7. Evaporators: Tube sheets are used in evaporators, which are used to evaporate a liquid and separate it from the dissolved solids or other impurities. The tube sheet supports the tubes and allows for efficient heat transfer.

|

| Product Tags: ASTM EN Heat Exchanger Parts Shell EN Heat Exchanger Parts ASTM Heat Exchanger Parts |

Related Products

|

Shell And Tube Heat Exchanger API 660 ASME U Stamp For Petrochemical Industry Application |

|

BV Inspected SA182 F11 GR.2 Tubesheet Shell And Tube Heat Exchanger TEMA R Type For Optimal Heat Transfer |

|

API 660 Shell And Tube Heat Exchanger TEMA Standard ASME U Stamp ASME VIII |

|

Fixed Tubesheet Shell and Tube Heat Exchanger AEL, BEM, NEN Type TEMA Class |

|

Shell and Tube Heat Exchanger API Standard 660, ASME VIII Division 1, TEMA R CLASS |

|

Heavy-duty Exchangers Floating Head Type H-AES Type TEMA RCB TEMA R CERTIFICATE |

Email to this supplier