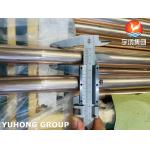

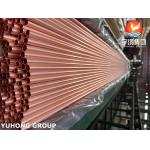

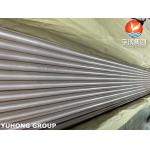

EN12449 CuZn20Al2As C68700 Brass Seamless Tube for Power Plants Condenser

|

Detailed Product Description

|

EN12449 CuZn20Al2As C68700 Brass Seamless Tube for Power Plants Condenser

Plant Condensers: Optimal Corrosion & Thermal Performance

EN12449 Chemical Compositions

EN12449 Mechanical Properties

EN12449 Supplementary Requirements (All Grades)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ASME SB111 Seamless Tube C71500 Seamless Tube C68700 Seamless Tube |

Related Products

|

ASTM B111 C70600 Copper Nickel Tube for Condenser , Heat Exchanger Application |

|

ASTM B111 / ASME SB111 C12200 Copper Nickel Tube for Condenser Heat Exchanger |

|

ASTM B111 / ASME SB111 C44300 Copper Nickel Tube for Condenser and Heat Exchanger Application |

|

ASTM B111 / ASME SB111 C71500 Copper Nickel Tube Heat Exchanger Tube |

|

ASTM B111 C68700 Copper Nickel Tube for Condenser and Heat Exchanger Application |

|

JIS H3300 C1220T Seamless Copper Alloy Tube For HVAC systems |

Email to this supplier