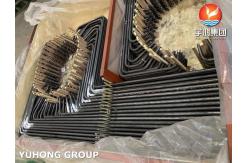

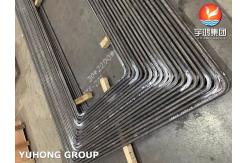

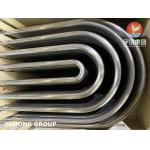

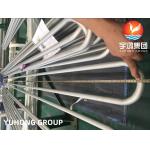

ASTM A179 Irregular Carbon Steel U Bend Tube Heat Exchanger Tube Boiler Tube

|

|

ASTM A179 Heat Exchanger Tube Low Carbon Steel Seamless U Bend Tube

The effect of irregular bend structures in oscillating heat pipes (OHPs) on thermal performance and unidirectional flow can be analyzed through several key mechanisms: Thermal Performance

Unidirectional Flow

ASTM A179 Carbon Steel Seamless Tube Chemistry Composition:

ASTM A179 Carbon Steel Seamless Tube Mechanical Properties:

ASTM A179 Carbon Steel Seamless Tube Outside Diameter & Tolerance

ASTM A179 Carbon Steel Seamless Tube Wall thickness & Tolerance

Other Available Materials

Applications:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ASTM A179 U Bend Tube Heat Exchanger U Bend Tube Seamless Carbon Steel U Bend Tube |

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |