ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe for Heat Exchanger

|

|

ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe for Heat Exchanger

YUHONG GROUP ASME SA312 seamless stainless tube, ASTM A312 welded seamless stainless tubes, ASTM A312 seamless stainless pipes, ASTM A312 welded seamless stainless pipes, TP304 TP304L TP304H stainless pipes, TP309S TP309H stainless pipes, TP310S TP310H stainless pipes, TP316 TP316L stainless pipes. TP321 TP321H stainless pipe, TP347 TP347H stainless pipe, seamless stainless pipe, welded stainless pipe, seamless stainless tube, welded stainless tube, Seamless Stainless-Steel Pipe

ANSI B16.10: B16.19 SCH 5S, SCH 10S, SCH 20, SCH 30, SCH 40S, SCH 60, SCH80S, XS, SCH 100, SCH 120, SCH160, XXS ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe for Heat Exchanger Chemical Composition

ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe Final Finishing:

Solution Annealed & Pickled ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe Supplementary Testing

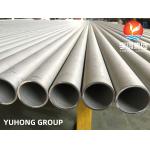

ASME SA312 TP304L Austenitic Stainless Steel Seamless Pipe Application

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: TP321H Stainless Steel Seamless Pipe TP316H Stainless Steel Seamless Pipe ASTM A312 Stainless Steel Seamless Pipe | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM A182 F5 Stainless Steel Weld Neck Flange RF / FF for Petrochemical Power Plants |

|

ASTM A511 TP316 316L 1.4404 Stainless Steel Seamless Pipe Pickled Annealed ABS Certification |

|

ASTM A312 TP321H Austenitic Stainless Steel Seamless Pipe for Oil and Gas Industry |

|

ASTM A312, A312M TP347H Stainless Steel Seamless Pipe Chemical Containers |

|

Round Stainless Steel Seamless Pipe ASTM A312, TP310H NDT Available |

|

ASTM A312 TP304 Pickled Surface Stainless Steel Seamless Pipe PT Available |