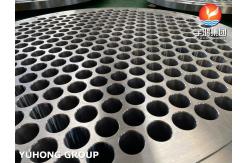

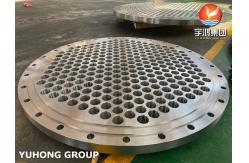

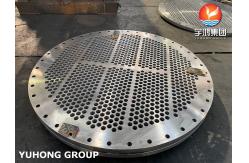

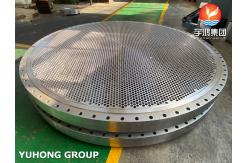

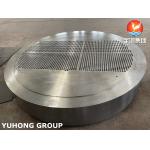

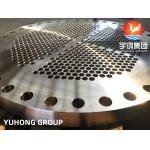

1.4541 Tube Plate EN10028-7 Forged Tubesheet For Heat Exchanger

|

|

X6CrNiMoTi17-12-2 1.4541 EN10028-7 Forged Tubesheet for Heat Exchanger

A tubesheet, the plate that forms the sealing surface at the end of a shell and tube heat exchanger or a pressure vessel. It provides a surface for the tube ends to be welded or secured to create a leak-proof joint. Such tubesheets are used in various industries, including petrochemical, chemical, and power generation, where corrosion resistance and high-temperature properties are required.

EN 10028-7 was originally published in 2000. The second edition, BS EN 10028-7:2007, replaced BS EN 10028-7:2000, which was withdrawn on January 31, 2008 by BSi. The third and current edition was published in 2016, replacing the 2007 edition, which has now been withdrawn. EN 10028-7 chemical composition tables

Other Materials

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 1.4541 Forged Tubesheet Heat Exchanger Forged Tubesheet EN10028-7 Forged Tubesheet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Normalized Carbon Steel Tubesheet Sa516 Gr.70n Heat Exchanger Component |

|

ASTM A182 Stainless Steel Baffle And Tubesheet For Heat Exchanger |

|

ASME SA516 Gr.70N Stationary Tubesheet Used In Heat Exchanger |

|

High Strength Steel Baffle And Tube Sheet Used In Heat Exchanger / Boiler / Air Conditing |

|

EN10028 1.4541 Stainless Steel Tube Sheet For Floating Head Exchanger Shell Heat Exchanger |

|

ASTM A182 F316L Stainless Steel Tubesheet For Heat Exchanger |