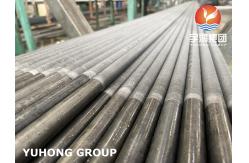

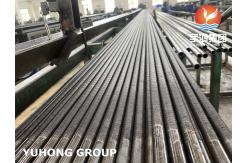

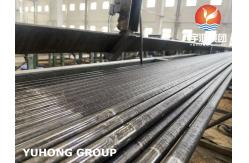

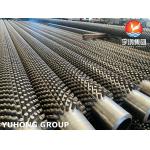

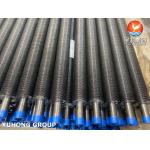

A179 Low Finned Tubing Extruded Fin Tubes For Heat Exchangers

|

A179 Low Finned Tubing Extruded Fin Tubes For Heat Exchangers

What is the Low Fin Tube?

A low fin tube, also known as a finned tube or a finned heat exchanger tube, is a type of tube used in heat transfer applications. It is designed to increase the surface area available for heat transfer between the fluid inside the tube and the surrounding environment. The tube itself is typically made of a smooth, seamless material such as copper, stainless steel, or carbon steel. The distinguishing feature of a low fin tube is the presence of external fins that extend radially from the tube surface. These fins are usually spiral or helical in shape and are uniformly spaced along the length of the tube. The purpose of the fins is to enhance heat transfer by increasing the surface area available for convection and radiation. The additional surface area allows for more efficient heat exchange between the fluid flowing inside the tube and the ambient air or another fluid outside the tube. The increased surface area provided by the fins can significantly improve the heat transfer rate and overall performance of the heat exchanger. Low fin tubes are commonly used in various applications where efficient heat transfer is required, such as air conditioning systems, refrigeration units, heat recovery systems, and power plants. They are particularly useful in applications where the temperature difference between the fluid inside the tube and the surrounding environment is relatively small. The term "low fin" refers to the relatively small height or size of the fins compared to other types of finned tubes. The specific design and dimensions of low fin tubes can vary depending on the application and desired heat transfer characteristics. Overall, low fin tubes play a crucial role in enhancing heat transfer efficiency and are widely employed in various industries to improve the performance of heat exchange systems.

Advantages of A179 material

It's important to note that the selection of the appropriate material for a specific application depends on several factors, including operating conditions, fluid properties, and compatibility requirements. Consulting with a qualified engineer or heat transfer specialist is recommended to ensure the optimal material choice for a given heat transfer system.

Chemical Compositions of A179 Tubes

Mechanical Properties of A179 Tubes

Wall Thickness Tolerance of A179 Tubes

Outside Diameter Tolerance of A179 Tubes

Length Tolerance of A179 Tubes

Hydrostatic Test Pressures of test requirements

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Heat Exchangers A179 Low Finned Tubing A179 Low Finned Tubing Extruded Fin Tubes For Heat Exchangers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASME SA209 TP304 Stainless Steel Embedded Fin Tube Fin Type G With Aluminum 1060 Fin |

|

Alloy Steel P22 High Frequency Welded Finned Tube For Heat Recovery |

|

Extruded Fin Tube , ASTM A179 Carbon Steel Low Fin Tube For Air Coolers |

|

Studded Fin Tube HFW Fin Tube Furnace Application |

|

Carbon Steel Embedded G-Type Fin Tube ASTM A210 Grade A1 Al 1060 |

|

ASTM A335 P9 With 11Cr Studded Tube For High Temperature Service |