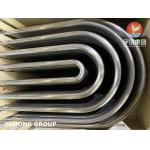

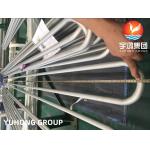

C68700 Copper Alloy U-Tube For Chillers HVAC Systems Seamless

|

C68700 Copper Alloy U-Tube For Chillers HVAC Systems Seamless

Overview

C68700 is a type of brass alloy that is commonly used in the

manufacturing of tubes. A C68700 seamless tube refers to a tube

that is made from this specific alloy without any welded seams

along its length. Seamless tubes are manufactured by piercing a

solid billet of metal and then drawing it through a series of dies

to achieve the desired dimensions and shape.

Features of C68700

C68700 is a type of brass alloy that is known for its excellent

corrosion resistance and thermal conductivity. Some key features of

C68700 brass alloy include:

Overall, C68700 brass alloy offers a combination of excellent

corrosion resistance, thermal conductivity, strength, and

workability, making it a popular choice for various industrial and

commercial applications.

Applications:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: HVAC Systems Copper Alloy U-Tube Seamless Copper Alloy U-Tube Chillers Copper Alloy U-Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |