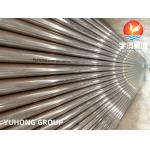

ASME SB111 C68700 Seamless Brass Tubes for Desalination of Seawater

C68700 is an aluminum brass alloy with arsenic addition,

specifically designed for harsh environments such as seawater

desalination. Its composition (Cu: 76-79%, Al: 1.8-2.5%, As:

0.02-0.06%, Zn: balance) ensures exceptional corrosion resistance

in seawater and high thermal conductivity. The arsenic content

further enhances resistance to dezincification, a critical feature

for long-term durability in marine applications.

The production process of Brass Tube

Raw Materials

Melting&Casting

Extrusion

Rolling

Intermediate Heat Treatment 1

Straightening

Three-line Drawing

Acid Washing

Intermediate Heat Treatment 2

Two Cascade Drawing

Cutting&Cleaning

Eddy Current Test

Final Heat Treatment

Packing

Shipping

Comparison Table of Brass Tube Alloy

Implementation Standard | Alloy Specifications |

GB/T 5231 | HAI 77-2 |

HSn70-1, HSn72-1 |

ASTM B111 | C68700 |

C44300 |

BS EN12451 | CuZn20Al2As |

CuZn28Sn1As |

JIS H3300 | C6870, C6871, C6872 |

C44300 |

AS 1569 | C68700 |

C44300 |

Chemical Composition of Brass Tube Alloys

Implementation Standard | Alloy | Cu (%) | Al/Sn (%) | As (%) | Fe (%) | Pb (%) | Other Impurities (%) | Zn (%) | Total Impurities (%) |

GB/T 5231 | HAl77-2 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | Balance | ≤0.6 |

ASTM B111 | C68700 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | Balance | ≥99.5 (Sum) |

ASME SB111 |

JIS H3300 | C6870 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.05 | ≤0.05 | ≤0.05 (Other) | Balance | - |

JIS H3300 | C6871 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.05 | ≤0.05 | ≤0.05 (Other); Si: 0.20-0.50 | Balance | - |

JIS H3300 | C6872 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.05 | ≤0.05 | ≤0.05 (Other); Ni: 0.20-1.0 | Balance | - |

BS EN12451 | CuZn20Al2As (CW702R) | 76.0-79.0 | 1.8-2.3 (Al) | 0.02-0.06 | ≤0.07 | ≤0.05 | Ni ≤0.1; P ≤0.01; Mn ≤0.1; ≤0.3 (Other total) | Balance | - |

AS 1569 | C68700 | 76.0-79.0 | 1.8-2.5 (Al) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | Balance | - |

GB/T 5231 | HSn70-1 | 69.0-71.0 | 0.8-1.3 (Sn) | 0.03-0.06 | ≤0.10 | ≤0.05 | ≤0.05 (Other) | Balance | ≤0.3 |

GB/T 5231 | HSn72-1 | 70.0-73.0 | 0.9-1.2 (Sn) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | Balance | ≤0.4 |

ASTM B111 | C44300 | 70.0-73.0 | 0.9-1.2 (Sn) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | Balance | ≥99.6 (Sum) |

ASME SB111 |

JIS H3300 | C4430 | 70.0-73.0 | 0.9-1.2 (Sn) | 0.02-0.06 | ≤0.05 | ≤0.05 | ≤0.05 (Other) | Balance | - |

BS EN12451 | CuZn28Sn1As (CW706R) | 70.0-72.5 | 0.9-1.3 (Sn) | 0.02-0.06 | ≤0.07 | ≤0.05 | Ni ≤0.1; P ≤0.01; Mn ≤0.1; ≤0.3 (Other total) | Balance | - |

AS 1569 | C44300 | 70.0-73.0 | 0.8-1.2 (Sn) | 0.02-0.06 | ≤0.06 | ≤0.07 | ≤0.07 (Other) | | |

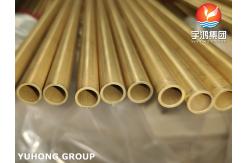

Primary Applications in Seawater Desalination

Heat Exchangers and Condensers

- C68700 tubes are widely used in multi-stage flash (MSF) and

reverse osmosis (RO) systems. Their high thermal conductivity

(64 BTU·in/(hr·ft²·°F)) ensures efficient heat transfer between

seawater and desalination equipment

- The seamless structure eliminates weld seams, reducing leakage

risks in high-pressure environments

Corrosion Resistance

- The aluminum content forms a protective oxide layer, while arsenic

prevents dezincification. This combination allows the tubes to

withstand saltwater, chlorine, and sulfide exposure, even at high

flow velocities

- Example: In seawater intake pipelines, C68700 resists pitting

and crevice corrosion, extending equipment lifespan

Mechanical Performance

- Tensile Strength: 345–600 MPa (minimum 345 MPa for annealed

tubes)

- Yield Strength: 125–540 MPa, suitable for high-pressure

condensers and evaporators.

- Fatigue Resistance: Maintains structural integrity under cyclic

thermal and mechanical stresses.