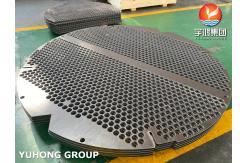

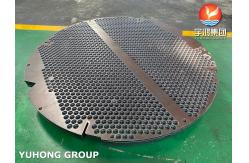

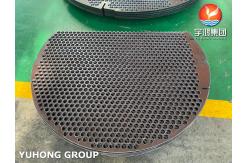

Customized Carbon Steel Baffle Plate Support Plate For Heat Exchanger

|

|

Carbon Steel Baffle Support Plate For Heat Exchanger

Baffle plates serve as obstructions within the heat exchanger, causing the fluid to change direction and creating turbulence. This turbulence enhances heat transfer efficiency by promoting better mixing and reducing the formation of stagnant zones. The design and positioning of baffles play a crucial role in optimizing the flow path and maximizing heat transfer. Drilling is indeed one of the primary machining processes used for baffle plates. The plates are typically thin and require holes to be drilled accurately to allow the passage of tubes and facilitate fluid flow. Stack drilling is commonly employed when multiple baffle plates are used for thicker or more complex baffle arrangements. The stack is clamped together, and the necessary holes are drilled simultaneously to ensure alignment and consistency among the plates.

Materials of Baffle Plate

The role of a baffle plate in a heat exchanger can be summarized as follows: 1. Enhancing Heat Transfer: Baffle plates extend the flow channel length on the shell side of a heat exchanger, allowing for increased flow velocity between the tubes. This leads to greater turbulence and improved heat transfer efficiency. The turbulent flow helps in breaking the boundary layer near the tube surface, facilitating better heat exchange between the fluids.

2. Supporting Heat Exchange Tubes: In horizontal heat exchangers, baffles provide support for the heat exchange tubes. They help counteract the compressive stress experienced by the tubes, especially when they are long. By increasing the number of baffles and reducing the distance between them, within the allowable pressure drop limit, the baffle plates help maintain the mechanical integrity of the tubes and prevent excessive vibration induced by fluid flow.

3. Facilitating Tube Installation: Baffles also play a role in simplifying the installation process of heat exchange tubes. They provide structural stability and serve as guides for tube placement, ensuring proper alignment within the heat exchanger. This makes the assembly and maintenance of the heat exchanger more convenient and efficient.

What the effect of the baffle plate?

Application boilers reservoirs hydraulic tanks pressure vessels wood burners steam turbines large central air conditioning units

|

|||||||||||||||||||||||||||

| Product Tags: Customized Carbon Steel Baffle Plate Carbon Steel Heat Exchanger Baffle Plate |

|

ASME SA516 Grade70N Carbon Steel Baffle for Shell and Tube Heat Exchanger |

|

ASME SA336 F5N High Temperature And Pressure Alloy Steel Forging For Heat Exchanger Baffle |

|

EN 10025-2 S235JR Carbon Steel Baffle Tubesheet For Heat Exchanger |

|

Heat Exchanger Parts Pressure Vessel Baffle Plate SA387 GR.11 CL.2 A36 |

|

ASME SA516 Gr 70 Carbon Steel Baffle Plate For Heat Exchanger |

|

ASTM A182 Stainless Steel Baffle For Pressure Vessels |