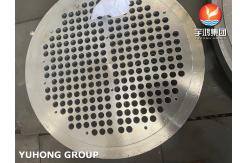

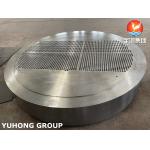

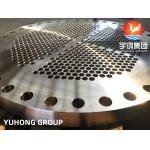

ASTM Copper Alloy Steel Baffle And Tubesheet For Heat Exchanger

|

|

ASTM Copper Alloy Steel Baffle And Tubesheet For Heat Exchanger

Copper alloy steel baffle and tubesheet are components commonly

used in heat exchangers and boilers. Copper alloy steel baffles and tubesheets are commonly used in heat

exchangers due to their excellent thermal conductivity, corrosion

resistance, and mechanical properties. These components play a

crucial role in maximizing heat transfer efficiency and ensuring

the long-term reliability of the heat exchanger.

Fixed Tubesheet Exchanger (L, M, and N Type Rear Headers)In a fixed tubesheet exchanger, the tubesheet is welded to the shell. This results in a simple and economical construction and the tube bores can be cleaned mechanically or chemically. However, the outside surfaces of the tubes are inaccessible except to chemical cleaning. If large temperature differences exist between the shell and tube materials, it may be necessary to incorporate an expansion bellows in the shell, to eliminate excessive stresses caused by expansion. Such bellows are often a source of weakness and failure in operation. In circumstances where the consequences of failure are particularly grave U-Tube or Floating Header units are normally used. This is the cheapest of all removable bundle designs, but is generally slightly more expensive than a fixed tubesheet design at low pressures.

U-Tube ExchangersIn a U-Tube exchanger any of the front header types may be used and the rear header is normally a M-Type. The U-tubes permit unlimited thermal expansion, the tube bundle can be removed for cleaning and small bundle to shell clearances can be achieved. However, since internal cleaning of the tubes by mechanical means is difficult, it is normal only to use this type where the tube side fluids are clean.

Floating Head Exchanger (P, S, T and W Type Rear Headers)In this type of exchanger the tubesheet at the Rear Header end is not welded to the shell but allowed to move or float. The tubesheet at the Front Header (tube side fluid inlet end) is of a larger diameter than the shell and is sealed in a similar manner to that used in the fixed tubesheet design. The tubesheet at the rear header end of the shell is of slightly smaller diameter than the shell, allowing the bundle to be pulled through the shell. The use of a floating head means that thermal expansion can be allowed for and the tube bundle can be removed for cleaning. There are several rear header types that can be used but the S-Type Rear Head is the most popular. A floating head exchanger is suitable for the rigorous duties associated with high temperatures and pressures but is more expensive (typically of order of 25% for carbon steel construction) than the equivalent fixed tubesheet exchanger. Considering each header and shell type in turn:

A-Type front headerThis type of header is easy to repair and replace. It also gives access to the tubes for cleaning or repair without having to disturb the pipe work. It does however have two seals (one between the tube sheet and header and the other between the header and the end plate). This increases the risk of leakage and the cost of the header over a B-Type Front Header.

B-Type front headerThis is the cheapest type of front header. It also is more suitable than the A-Type Front Header for high pressure duties because the header has only one seal. A disadvantage is that to gain access to the tubes requires disturbance to the pipe work in order to remove the header.

C-Type front headerThis type of header is for high pressure applications (>100 bar). It does allow access to the tube without disturbing the pipe work but is difficult to repair and replace because the tube bundle is an integral part of the header.

D-Type front headerThis is the most expensive type of front header. It is for very high pressures (> 150 bar). It does allow access to the tubes without disturbing the pipe work but is difficult to repair and replace because the tube bundle is an integral part of the header.

N-Type front headerThe advantage of this type of header is that the tubes can be accessed without disturbing the pipe work and it is cheaper than an A-Type Front Header. However, they are difficult to maintain and replace as the header and tube sheet are an integral part of the shell.

Y-Type front headerStrictly speaking this is not a TEMA designated type but is generally recognized. It can be used as a front or rear header and is used when the exchanger is to be used in a pipe line. It is cheaper than other types of headers as it reduces piping costs. It is mainly used with single tube pass units although with suitable partitioning any odd number of passes can be allowed.

E-Type shellThis is most commonly used shell type, suitable for most duties and applications. Other shell types only tend to be used for special duties or applications.

F-Type shellThis is generally used when pure countercurrent flow is required in a two tube side pass unit. This is achieved by having two shells side passes—the two passes being separated by a longitudinal baffle. The main problem with this type of unit is thermal and hydraulic leakage across this longitudinal baffle unless special precautions are taken.

G-Type shellThis is used for horizontal thermosyphon reboilers and applications where the shellside pressure drop needs to be kept small. This is achieved by splitting the shellside flow.

H-Type shellThis is used for similar applications to G-Type Shell but tends to be used when larger units are required.

J-Type shellThis tends to be used when the maximum allowable pressure drop is exceeded in an E-Type Shell even when double segmental baffles are used. It is also used when tube vibration is a problem. The divided flow on the shellside reduces the flow velocities over the tubes and hence reduces the pressure drop and the likelihood of tube vibration. When there are two inlet nozzles and one outlet nozzle this is sometimes referred to as an I-Type Shell.

K-Type shellThis is used only for reboilers to provide a large disengagement space in order to minimize shellside liquid carry over. Alternatively a K-Type Shell may be used as a chiller. In this case the main process is to cool the tube side fluid by boiling a fluid on the shellside.

X-Type shellThis is used if the maximum shellside pressure drop is exceeded by all other shell and baffle type combinations. The main applications are shellside condensers and gas coolers.

L-Type rear headerThis type of header is for use with fixed tubesheets only, since the tubesheet is welded to the shell and access to the outside of the tubes is not possible. The main advantages of this type of header are that access can be gained to the inside of the tubes without having to remove any pipework and the bundle to shell clearances are small. The main disadvantage is that a bellows or an expansion roll are required to allow for large thermal expansions and this limits the permitted operating temperature and pressure.

M-Type rear headerThis type of header is similar to the L-Type Rear Header but it is slightly cheaper. However, the header has to be removed to gain access to the inside of the tubes. Again, special measures have to be taken to cope with large thermal expansions and this limits the permitted operating temperature and pressure.

N-Type rear headerThe advantage of this type of header is that the tubes can be accessed without disturbing the pipe work. However, they are difficult to maintain and replace since the header and tube sheet are an integral part of the shell.

P-Type rear headerThis is an outside packed floating rear header. It is, in theory, a low cost floating head design which allows access to the inside of the tubes for cleaning and also allows the bundle to be removed for cleaning. The main problems with this type of header are:

In practice it is not a low cost design, because the shell has to be rolled to small tolerances for the packing to be effective.

S-Type rear headerThis is a floating rear header with backing device. It is the most expensive of the floating head types but does allow the bundle to be removed and unlimited thermal expansion is possible. It also has smaller shell to bundle clearances than the other floating head types. However, it is difficult to dismantle for bundle pulling and the shell diameter and bundle to shell clearances are larger than for fixed head type exchangers.

T-Type rear headerThis is a pull through floating head. It is cheaper and easier to remove the bundle than with the S-Type Rear Header, but still allows for unlimited thermal expansion. It does, however, have the largest bundle to shell clearance of all the floating head types and is more expensive than fixed header and U-tube types.

U-tubeThis is the cheapest of all removable bundle designs, but is generally slightly more expensive than a fixed tubesheet design at low pressures. However, it permits unlimited thermal expansion, allows the bundle to be removed to clean the outside of the tubes, has the tightest bundle to shell clearances and is the simplest design. A disadvantage of the U-tube design is that it cannot normally have pure counterflow unless an F-Type Shell is used. Also, U-tube designs are limited to even numbers of tube passes.

W-Type rear headerThis is a packed floating tubesheet with lantern ring. It is the cheapest of the floating head designs, allows for unlimited thermal expansion and allows the tube bundle to be removed for cleaning. The main problems with this type of head are:

It is also possible for the shell and tube side fluids to become mixed if leakage occurs.

some specific applications of these components:

|

| Product Tags: Copper Alloy Steel Baffle Plate ASTM Heat Exchanger Tubesheet Industrial Steel Baffle Plate |

|

Normalized Carbon Steel Tubesheet Sa516 Gr.70n Heat Exchanger Component |

|

ASTM A182 Stainless Steel Baffle And Tubesheet For Heat Exchanger |

|

ASME SA516 Gr.70N Stationary Tubesheet Used In Heat Exchanger |

|

High Strength Steel Baffle And Tube Sheet Used In Heat Exchanger / Boiler / Air Conditing |

|

EN10028 1.4541 Stainless Steel Tube Sheet For Floating Head Exchanger Shell Heat Exchanger |

|

ASTM A182 F316L Stainless Steel Tubesheet For Heat Exchanger |