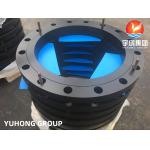

SB151 C70600 1¼ Inch SCH40 Class150 Weldneck Copper Nickel Flanges ASME B16.5 ASTM B151 UNS C70600 Copper Nickel Alloy Flange is a type of flange made from a composition of 90% copper and 10%

nickel. This blend of copper and nickel provides excellent

corrosion resistance, making it suitable for various applications.

The presence of nickel, iron, and manganese enhances its ability to

withstand corrosive elements. Cu-Ni 90/10 weld neck flanges are

commonly used in seawater piping systems, crankshafts, tubes for

light-duty condensers, sea water pipe-work desalination units, and

offshore platforms. These flanges are specifically designed to

offer durability and resistance to harsh environments.

SB151 C70600 1-1/4 Inch SCH40 Class150 Weldneck Copper Nickel

Flanges ASME B16.5 Equivalent Grades: GRADE | UNS | WNR. | EN | AFNOR | Cu-Ni 90/10 | C70600 | 2.0872 | NiCr20CuMo | Z2NCUD31-20AZ |

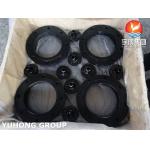

SB151 C70600 1-1/4 Inch SCH40 Class150 Weldneck Copper Nickel

Flanges ASME B16.5 Specification: Specification | ASTM B151 UNS C70600 | Type Of Flange | Weld Neck, Blind, Slip-On, Socket-Weld, Lap Joint, Threaded | Size | 1/2" To 48" | Available Type | Plate / Forged/ Threaded | Standards | ANSI/ASME B16.5, API7S-15, IS 2062, ISO70051, API, API7S-43, ASME

B16.48, AWWA C207, B16.47 Series A & B, API605, BS4504, EN1092,

UNI, ASME B16.36, DIN, BS1560-3.1, EN-1092, ISO, MSS S44 | Pressure Rating Class | Class 150 To Class 2500 | Face Type | Ring Type Joint, Flat Face, Lap-Joint Face, Raised Face, Large

Tongue & Groove And Small Tongue Groove, Large Male-Female And

Small Male-Female | Technique | Heat Treated/ Machined/ Forged |

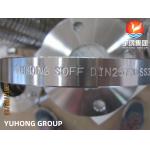

SB151 C70600 1-1/4 Inch SCH40 Class150 Weldneck Copper Nickel

Flanges ASME B16.5Chemical Composition: Cu | Mn | Pb | Ni | Fe | Zn | 88.6 min | 1.0 max | 0.05 max | 9-11 | 1.8 max | 1 max |

SB151 C70600 1-1/4 Inch SCH40 Class150 Weldneck Copper Nickel

Flanges ASME B16.5 Mechanical Properties: Density | Elongation | Yield Strength (0.2%Offset) | Tensile Strength | Melting Point | 0.323 lb/in3 | 30 % | 20000 psi | 50000 psi | 2260 F |

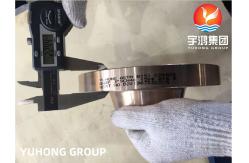

Copper-nickel weld neck flanges can be used in the following areas This makes copper-nickel alloy weld neck flanges suitable for shipbuilding, desalination, offshore platforms, power generation,

cooling systems, food processing plants and more.

The characteristics of necked butt weld flanges are as follows Resistant to biological contamination, erosion, stress and

corrosion Able to withstand high pressure Suitable for applications with wide temperature fluctuations Ensure a strong connection Withstand turbulence Copper-nickel butt-welding flanges have a high initial installation

cost but a long service life

|