ASTM A106 Gr.B Seamless Studded Fin Tube For

Boiler/Furnace Application

What's the description of studded fin tube?

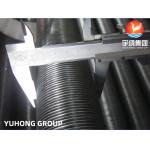

A studded fin tube is a type of heat exchanger tube that is

designed to enhance heat transfer efficiency. It consists of a base

tube with small studs or fins attached to its outer surface. These

studs or fins increase the surface area of the tube, allowing for

improved heat transfer between the fluid inside the tube and the

surrounding environment.

The studs or fins on the tube create turbulence in the fluid flow,

which helps to break up the boundary layer and enhance heat

transfer. This design is commonly used in applications where high

heat transfer rates are required, such as in boilers, air coolers,

and heat exchangers.

Studded fin tubes are often made from materials such as carbon

steel, stainless steel, or copper, depending on the specific

application and operating conditions. They are widely used in

industries such as power generation, petrochemical, and HVAC

(heating, ventilation, and air conditioning) systems.

Overall, the studded fin tube design is aimed at maximizing heat

transfer efficiency and improving the performance of heat

exchangers in various industrial applications.

What's the description of ASTM A106 Gr.B?

ASTM A106 Gr.B is a specification for seamless carbon steel pipe

intended for high-temperature service. It is commonly used in

various industries such as oil and gas, power generation, and

refineries.

The "ASTM" in the name refers to the American Society for Testing

and Materials, which sets standards for various materials and

products. "A106" is the specific designation for seamless carbon

steel pipe, and "Gr.B" indicates the grade of the steel.

ASTM A106 Gr.B pipes are manufactured using a seamless process,

which means they are formed without any welding or joining. This

results in a pipe with a uniform composition and strength

throughout its length.

The "Gr.B" grade signifies that the steel used in the pipe has a

minimum yield strength of 35,000 psi (240 MPa) and a minimum

tensile strength of 60,000 psi (415 MPa). This grade of steel is

suitable for high-temperature applications, as it can withstand

elevated temperatures and pressures.

ASTM A106 Gr.B pipes are commonly used for conveying fluids and

gases at high temperatures and pressures. They are known for their

excellent durability, corrosion resistance, and ability to

withstand harsh operating conditions.

It is important to note that ASTM A106 Gr.B is just one of many

specifications available for carbon steel pipes, and the selection

of the appropriate specification depends on the specific

requirements of the application.

Mechanical Property for ASTM A106 Carbon Steel Tube

| Standard | Grade | Tensile

Strength (Mpa) | Yield

Strength (Mpa) | Elongation

(%) |

| A106 | A | ≥330 | ≥205 | ≥35 |

| B | ≥415 | ≥240 | ≥30 |

| C | ≥485 | ≥275 | ≥30 |

Chemical Composition for ASTM A106 Carbon Steel Tube

| Standard | Grade | C | Si | Mn | P | S | Mo | Cr | V |

| A106 | A | ≤0.25 | ≥01.0 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 |

Studded pipe advantages:

Because of their relatively thicker Cross-section as compared to

fins, Studded pipe is one of the mechanically Strongest

extended-surfaces Available. Although strength may not be a

consideration for heat Transfer performance, it may be important

when the application requires the extended surface to carry the

weight of the tube at supports, or where severe mechanical abuse is

expected in service or during cleaning.

What's the application of A106 Gr.B seamless studded fin tube?

The A106 Gr.B seamless studded fin tube is commonly used in various

industrial applications where high heat transfer rates and corrosion resistance are

required. Some potential applications of A106 Gr.B seamless studded

fin tubes include:

1. Boilers: A106 Gr.B seamless studded fin tubes are often used in

boiler systems to enhance heat transfer efficiency and improve

overall performance. They help in transferring heat from the

combustion gases to the water or steam within the boiler.

2. Heat Exchangers: These fin tubes are utilized in heat exchangers

to facilitate efficient heat transfer between two fluids. They are

commonly found in applications such as air coolers, condensers, and

oil coolers.

3. Petrochemical Industry: A106 Gr.B seamless studded fin tubes are

suitable for use in the petrochemical industry, where they can be

employed in processes involving heat transfer, such as in heat

exchangers for refining and processing various chemicals.

4. Power Generation: These fin tubes find application in power

plants, particularly in steam generators and heat recovery steam

generators (HRSGs). They assist in transferring heat from the

exhaust gases to the water or steam, improving energy efficiency.

5. HVAC Systems: A106 Gr.B seamless studded fin tubes can be used

in heating, ventilation, and air conditioning (HVAC) systems for

efficient heat transfer between the air and the refrigerant or

water.