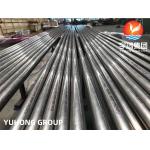

ASTM A335 P91 K91560 Alloy Steel Seamless Pipe for High Temperature

|

|

ASTM A335 P91 K91560 Alloy Steel Seamless Pipe for High Temperature

What is ASTM A335?

This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for hightemperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

P91 Chemical Composition

P91 Equivalent Grades

ASTM A335 P91 Mechanical Properties

A335 is often called chrome moly pipe because of the chemical makeup of Mo and Cr. Mo increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. It also enhances the corrosion resistance of steel, and inhibits pitting.

PMI

Size Inspection

A335 seamless steel pipe is a popular choice for high temperature applications due to several key reasons:

High temperature resistance: A335 seamless steel pipe is designed to withstand temperatures up to 600°C (1112°F), making it an ideal material for high-temperature applications such as steam pipes and heat exchangers.

Applications

|

|

ASTM A213 T5 Alloy Steel Seamless Boiler Tube |

|

ASTM A335 T11 Seamless Alloy Steel Pipe for High-Temperature Service |

|

ASTM B163 N04400 Seamless Alloy Steel Tube for Heat Exchangers |

|

ASTM B407 ASME SB407 N08810 Alloy Steel Heat Exchanger Tube |

|

SA213 T11 Seamless Ferritic Alloy Steel Tube For Power Plant Boilers |

|

ASTM B163 Monel 400 UNS N04400 Seamless Nickel Copper Alloy Tube Bright Surface |