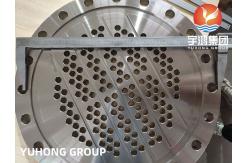

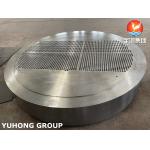

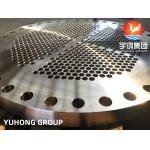

ASTM A182 / ASME SA182 F316L Stainless Steel Tubesheet Heat Exchanger Part

|

|

ASTM A182 / ASME SA182 F316L Stainless Steel Tubesheet Heat Exchanger Part ASTM A182 F316L is American standard forged stainless steel, according to ASTM A182/A182M-2018 ASTM A182 F316L stainless steel is commonly used in pulp and paper equipment heat exchangers, dyeing equipment, film washing equipment, pipelines, coastal area building external materials, as well as high-end watch chains, watch cases, etc. Seawater equipment, chemicals, dyes, papermaking, oxalic acid, fertilizer and other production equipment; Photography, food industry, coastal facilities, ropes, CD rods, bolts, nuts. A182 F316L is molybdenum containing stainless steel, due to the molybdenum contained in steel, under high temperature conditions, when the concentration of sulfuric acid is less than 15% or higher than 85%, A182 F316L stainless steel has a wide range of uses. A182 F316L stainless steel also has good resistance to chloride attack, so it is usually used in Marine environments. ASTM A182 F316L stainless steel has a maximum carbon content of 0.03 and can be used in applications that cannot be annealed after welding and require maximum corrosion resistance. 316L stainless steel is a high quality steel material with many unique properties. This steel is widely used not only in manufacturing and construction, but also in the medical and food processing industries. Here are five features of 316L steel and their applications. Corrosion resistance 316L stainless steel is a low-carbon stainless steel with excellent corrosion resistance, especially in chloride ion environments. Therefore, it is widely used in Marine engineering, chemical, pulp and paper and other industries, can be used in harsh environments for a long time, reducing the cost of equipment maintenance and replacement. High temperature performance The high temperature resistance of 316L steel is excellent and can withstand temperatures up to 870°C. The high temperature resistance of this steel makes it ideal for high temperature equipment manufacturing, such as oil refining and chimney manufacturing. Good machinability and weldability Due to the low carbon content contained in 316L steel, it has excellent machinability and weldability. This makes 316L steel ideal for building pressure vessels and other complex shapes. Excellent toughness and strength 316L steel not only has excellent toughness and strength, but also maintains excellent performance at extremely low temperatures. The high toughness and strength of this steel make it ideal for manufacturing equipment used in extreme environments, such as nuclear power plants and aerospace equipment. Wide application 316L steel has excellent properties and is therefore widely used in the medical and food processing industries. Because it does not cause any harm to the human body, it is widely used in the manufacture of medical instruments such as surgical instruments and artificial joints. In the food processing industry, 316L steel is widely used in the manufacture of containers and pipes and other equipment to ensure the hygiene and quality of food. Material Grades of Tubesheet

|

|||||||||||||||||||||||||

| Product Tags: F316L Stainless Steel Tubesheet ASTM A182 Stainless Steel Tubesheet Heat Exchanger Stainless Steel Tubesheet |

|

Normalized Carbon Steel Tubesheet Sa516 Gr.70n Heat Exchanger Component |

|

ASTM A182 Stainless Steel Baffle And Tubesheet For Heat Exchanger |

|

ASME SA516 Gr.70N Stationary Tubesheet Used In Heat Exchanger |

|

High Strength Steel Baffle And Tube Sheet Used In Heat Exchanger / Boiler / Air Conditing |

|

EN10028 1.4541 Stainless Steel Tube Sheet For Floating Head Exchanger Shell Heat Exchanger |

|

ASTM A182 F316L Stainless Steel Tubesheet For Heat Exchanger |