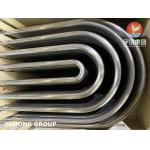

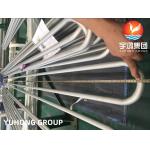

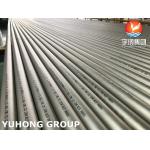

ASTM A213 TP304 Stainless Steel Seamless U Bend Tube For Heat Exchanger

|

|

ASTM A213 TP304 Stainless Steel U Bend Tube

ASTM A213 TP304 is a standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. It covers a variety of grades, including TP304, which is a commonly used stainless steel grade.

The U bend tube refers to a specific type of tube that has been bent into the shape of a "U." These tubes are commonly used in heat exchangers, condensers, and other applications where a compact design is required.

The benefits of U Bend Tube:

1>.Space-saving design: U-bend tubes allow for a compact and efficient use of space, especially in heat exchangers and condensers. The U-bend shape helps to reduce the overall length of the tube bundle, making it suitable for applications with limited space.

2>.Reduced stress and fatigue: U-bend tubes are designed to minimize stress and fatigue at the bend region. The smooth curvature of the U-bend helps distribute stress evenly, reducing the chances of tube failure due to fatigue or excessive stress concentrations.

3>.Enhanced heat transfer: The U-bend design promotes enhanced heat transfer by creating turbulence and improving fluid flow characteristics. This allows for better heat exchange efficiency in applications where heat transfer is crucial.

4>.Simplified installation and maintenance: U-bend tubes can be easily installed and replaced, making maintenance and repairs more manageable. The U-bend shape allows for straightforward tube installation, particularly in confined spaces.

5>.Cost-effective solution: U-bend tubes offer a cost-effective solution for applications requiring compact heat exchangers. The reduced material and space requirements can result in overall cost savings, making them a popular choice in various industries.

Chemical Composition of ASTM A213 TP304

Mechanical Properies of ASME SA213 TP304

Wall Thickness Tolerance of ASME SA213

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM B163 Incoloy N02200 N02201 N04400 N06600 Heat Exchanger Tube |

|

Nickel Alloy U Bend Tube ASME SB163 Monel 400 UNS N04400 Seamless Tube |

|

ASTM B163 Incoloy 800HT UNS N08811 Bright Surface Nickel Alloy Tube |

|

ASME SB163 UNS N04400 / Monel 400 Nickel Alloy Seamless Heat Exchanger Tube |

|

UNS NO6625/Din 2.4856/ASTM B444 Inconel 625 U Bend Tube Chemical Process Equipment NDT Available |

|

ASTM B622 / ASME SB622 Hastelloy C22 (UNS NO6022 ) Seamless Tube, Heat Exchanger /Boiler Application |