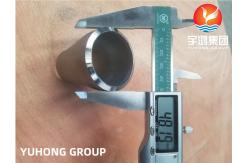

ASTM B366 Inconel 600 / UNS N06600 Concentric Reducer Nickel Alloy Buttweld Fitting

|

|

ASTM B366 Inconel 600 / UNS N06600 Concentric Reducer Nickel Alloy Buttweld Fitting

Overview:

Inconel 600 is a versatile superalloy primarily composed of nickel and chromium, offering excellent resistance to oxidation and corrosion, particularly in high-temperature environments. A concentric reducer crafted from Inconel 600 is designed to connect pipes of different diameters, allowing for a smooth transition that minimizes turbulence and maintains flow efficiency.

These reducers are typically utilized in critical applications, including chemical processing, aerospace, nuclear engineering, and power generation, where the material's ability to withstand extreme conditions is paramount. The high tensile strength of Inconel 600 ensures durability even under high-pressure scenarios.

The fabrication process may include techniques such as hot or cold working, and the reducers can be produced in various sizes to fit specific piping requirements. Their construction guarantees a tight seal and helps prevent leakage, contributing to safety and reliability in demanding environments.

Inconel 600's non-magnetic properties and excellent weldability further enhance its appeal for precise engineering applications. The reducers are often surface-treated to improve longevity and performance, making them a go-to option for engineers requiring robust solutions in harsh conditions.

Specification:

Chemical Composition:

Mechanical Properties:

Dimension:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: INCONEL 600 Steel Pipe Fittings UNS N06600 Concentric Reducer Nickel Alloy Concentric Reducer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

B366 Hastelloy C22 180° LR Elbow Long Radius Butt Weld Fitting |

|

STAINLESS STEEL N08904 BUTT WELD FITTING SB366 WP904L EBLOW B16.9 |

|

ASTM B366 N08810 Incoloy 800H 1.4958 180 DEG Elbow Buttweld B16.9 |

|

A403 WP321H Elbow 90/180 Deg , Stainless Steel Butt Weld Fitting B16.9 |

|

ASTM A403 WP304-S 90DEG. Stainless Steel Elbow BW Fittings |

|

Forged Steel Pipe Fittings NPT SW 3000# A182 / A105 B16.11 |