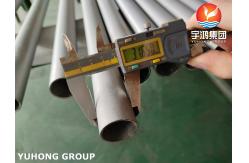

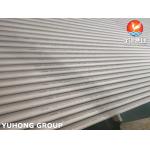

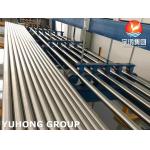

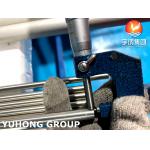

High Tensile Strength ASTM A268 TP410 1.4006 S41000 Seamless Tube

|

|

High Tensile Strength ASTM A268 TP410 1.4006 S41000 Seamless Tube

ASTM A268 is Standard specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service, the grades contain TP410, TP405, TP420, TP430, TP430Ti, TP403, TP409, TP444, TP439 and TP446.

This specification covers a number of grades of nominal-wall-thickness, stainless steel tubing for general corrosion-resisting and high-temperature service. Most of these grades are commonly known as the “straight-chromium” types and are characterized by being ferromagnetic. Two of these grades, TP410 and UNS S41500, are amenable to hardening by heat treatment, and the high-chromium, ferritic alloys are sensitive to notch-brittleness on slow cooling to ordinary temperatures. These features should be recognized in the use of these materials.

410 contains the minimum amount of chromium to impart stainless steel properties. 410 resists oxidation and scaling up to 1200 degF. Hardness is one of 410’s best features; It resists abrasion and wear better than most 300 series stainless steel.

What are manufacturing types of ASTM A268 TP410 tube?

To produce SA 268 tp410 round tubing, there seem to be three

different manufacturing processes: seamless, welded, and ERW.

Chemical Composition of TP410

Equivalent Material of TP410

ASTM A268 TP 410 Tubing Mechanical Properties

Applications

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

ASTM A268 TP430Ti / UNS S43036 / 1.4510 Stainless Steel Seamless Tube |

|

Stainless Steel Seamless Tube ASTM A269 TP304L Pickled and Annealed Tubing |

|

ASTM A213 TP316L Stainless Steel Seamless Tube For Storage Tanks And Refineries |

|

ASTM A270 TP316L Stainless Steel Sanitary Seamless Tube Bright Surface |

|

SS ASME SA269 / ASTM A269 TP316L Seamless Tube Bright Annealing |

|

ASTM A270 TP316L Sanitary Stainless Steel Tube Seamless Tube for Chemical Engineering |