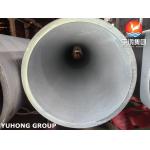

ASTM A790 S32750 Duplex Stainless Steel Pipe for Chemical and Industrial Application

|

|

ASTM A790 S32750 Duplex Stainless Steel Pipes for Chemical and

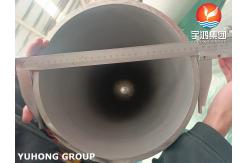

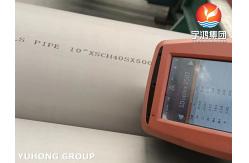

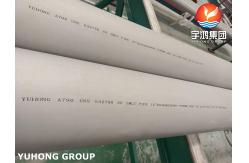

Industrial Application This standard is the standard specification for ferritic austenitic stainless steel pipes used in corrosive environments. ASTM A790 specifies the elements and requirements for the manufacturing of seamless and welded pipes, and requires the welding of dual phase steel and super dual phase steel pipes without adding any filler metal. When using UNS S31803, S32205, S32750, S32760, and S32520 duplex steel materials to produce steel pipes, corrosion testing should be supplemented. The ASTM A790 standard covers steel pipes with diameters ranging from 1/8 "(10.29mm) to 30" (762.0mm) and wall thicknesses ranging from 1.24mm to 12.7mm. Based on ANSI B36.10 for steel pipes, larger diameter steel pipes can be provided according to the A790 standard. What material is S31803? S31803 is the Unified Numbering System (UNS) name for the original duplex stainless steel. The UNS system was jointly created by multiple trading groups in the 1970s to reduce confusion caused by the same alloy being referred to as different things, and vice versa. Each metal is represented by a letter followed by five numbers, where the letter represents the metal series and S represents stainless steel.

The UNS S31803 (ASTM F51) specification has been largely replaced by UNS S32205 (1.4462,

ASTM F60). This reflects their desire to maximize the corrosion

performance of the alloy, thanks to the development of AOD

steelmaking technology, which allows for stricter control of

composition. In addition, it also allows for the addition level of

nitrogen to be affected, rather than simply being present as a

background element. Therefore, the highest performing dual phase

steel seeks to maximize the content of chromium (Cr), molybdenum

(Mo), and nitrogen (N).In most environments (including seawater),

S31803 has better corrosion resistance than austenitic grades (such

as alloy 316L). This brand has excellent resistance to

intergranular corrosion, pitting and Crevice corrosion, and

resistance to chloride stress corrosion cracking at temperatures up

to 150 º C.UNS S31803 is a ferritic austenitic stainless steel that

combines many beneficial characteristics of ferrite and austenitic

steel. Due to the high content of chromium and molybdenum, this

steel has excellent pitting corrosion and uniform resistance to

stress corrosion cracking corrosion, as well as high mechanical

strength.UNS S31803 has good weldability and can be welded using

most welding techniques of stainless steel. Due to the balanced

composition, when welding correctly, the heat affected zone

contains sufficient austenite to avoid the risk of local corrosion. Chemical Composition

Mechanical Properties

ASTM A790 Duplex Stainless Steel Pipes Applications 1. Chemical processing, Transport and Storage. 2. Oil and gas exploration and offshore rigs. 3. Oil and gas refining. 4. Marine environments. 5. Pollution control equipment. 6. Pulp and paper manufacturing. 7. Chemical process Plant. |

||||||||||||||||||||||||||||||||||||

| Product Tags: Industry Duplex Stainless Steel Tube Duplex Stainless Steel Pipes ASTM A790 Duplex Stainless Steel Pipes S31803 | ||||||||||||||||||||||||||||||||||||

|

ASME A789 S31803 Seamless Tube 25.4*1.24*11800MM Duplex Stainless Steel Tubes |

|

Duplex Stainless Steel Pipe, ASTM A790 , ASTM A928 , S31803 , S32750, S32760, S31254 , 254Mo, 253MA |

|

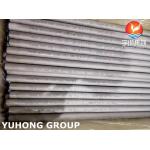

Duplex Steel Pipes , Super Duplex Pipes, A789, A790 , A928 S31803(2205) S32750 (2507) S32760 |

|

Super Duplex Stainless Steel Pipes, EN 10216-5 1.4462 / 1.4410, UNS32760(1.4501), Pickled & Annealed, ,20ft |

|

ASTM A790 / ASME SA790 S31803 Duplex Stainless Steel Pipe |

|

ASTM A790 duplex steel seamless pipe, UNS S31803 / S32205 (Duplex 2205), Thick Wall thickness |