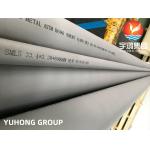

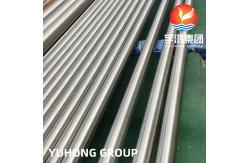

ASTM B861 GR.2 Titanium Alloy Pipe Seamless Heat Exchanger

Application

The ASTM B861 specification covers the requirements for 34 grades

of titanium and titanium alloy seamless pipe intended for general

corrosion resisting and elevated temperature service. Produced

through processes such as hot extrusion, hot rolling, or cold

drawing to ensure that the pipe body has no welds and uniform

overall performance. ASTM B861 GR.2 is typically supplied in an

annealed state to achieve optimal plasticity, toughness, and

corrosion resistance, facilitating subsequent bending, welding, and

processing. It may also provide a cold working state with higher

strength and slightly lower plasticity.

ASTM B861 Chemical Composition Requirements (%) | Composition | Grade1 (R50250) | Grade2 (R50400) | | Carbon | 0.08 | 0.08 | Oxygen | 0.18 | 0.25 | Nitroge | 0.03 | 0.03 | Hydrogen | 0.015 | 0.015 | | Iron | 0.20 | 0.30 |

What are the core characteristics and advantages of ASTM B861 GR.2

Titanium Alloy Pipe? - Excellent Corrosion Resistance: ASTM B861 GR.2 titanium alloy pipe can form a stable and dense

titanium oxide (TiO2) protective film in oxidizing environments

such as seawater, salt water, wet chlorine, hypochlorite, nitric

acid, chromic acid, etc., which protects the tube from corrosion.

At the same time, its corrosion resistance in chloride ion

environments is much better than stainless steel, and its

sensitivity to crevice corrosion is also higher than GR.7, GR.12

and other higher alloyed titanium materials.

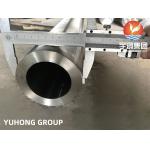

- Good Mechanical Properties & Fabricability: The strength of ASTM B861 GR.2 titanium alloy pipe belongs to the

medium strength grade of industrial pure titanium, which is

stronger than Gr. 1 and weaker than Gr. 3. It is enough to meet the

needs of many chemical and marine engineering applications, while

maintaining good plasticity and high elongation, usually greater

than or equal to 20%, and is easy to form by cold bending, flaring,

flanging and other forming processes. However, due to the low

thermal conductivity, low elasticity and stickiness of ASTM B861

GR.2, it is necessary to select appropriate cutting tools and

cutting parameters.

- Good Biocompatibility: ASTM B861 Gr. 2 pure titanium is one of the most biocompatible

metal materials and is widely used in human implants such as bone

screws, bone plates, joint components, and medical devices such as

surgical instruments and diagnostic equipment components. However,

when used as an implant, it usually needs to meet more stringent

special standards, such as ASTM F67.

What are the nondestructive testing requirements for ASTM B861 GR.2

Titanium Alloy Pipe?

The ASTM B861 GR.2 titanium alloy pipe should be subjected to a

hydrostatic test or a nondestructive electric test (usually

referred to as an eddy current test). At the same time, according

to customer requirements, more stringent tests can be provided,

such as Ultrasonic Testing (UT), which is used to detect

longitudinal and transverse defects, cracks, inclusions, folds,

etc. According to ASTM E213 standards, with high sensitivity; Eddy

Current Testing (ET), which is mainly used to detect surface and

near-surface defects according to ASTM E426/E426M standards.

ASTM B861 GR.7 Titanium Alloy Steel Heat Exchanger Pipe Application

Area - Chemical & Petrochemical: heat exchangers (tube/shell), condensers, reactors, containers,

pipeline systems for transporting corrosive media such as

chlor-alkali, nitric acid, and organic chlorides.

- Marine Engineering & Desalination: seawater cooling system pipelines, seawater desalination

equipment, ship pipeline systems, offshore platform structures and

pipelines.

- Power Generation: power station condenser tubes, flue gas desulfurization (FGD)

system components, geothermal system pipelines.

- Aerospace: hydraulic system pipelines, engine nacelles, environmental control

system pipelines.

- Medical & Pharmaceutical: medical devices, pharmaceutical equipment pipelines.

|